Thermal Management

The Need for thermal management

As semiconductors and other components shrink, circuits are becoming more integrated. Advanced functional electronic devices such as smartphones are becoming thinner, and their structures are increasingly complex. The heat generated by these components may interfere not only with the reliability of the products but also with their safety. Effective heat management is absolutely required for advanced devices.

Thermal management

We offer thermal interface materials (TIM), heatsinks, heat spreaders, and other items. We can also offer design proposals using advanced heat simulation technologies. Our heat dissipation solutions help to improve the performance and lifespan of electronic devices.

Addressing customer challenges with thermal management expertise

We provide our customers with thermal solutions by offering a wide range of thermal management products. We are also continuously engaged in new product development to expand our thermal management product lineup. Leveraging our extensive thermal technology and experience, we propose optimal solutions.

Thermal technology

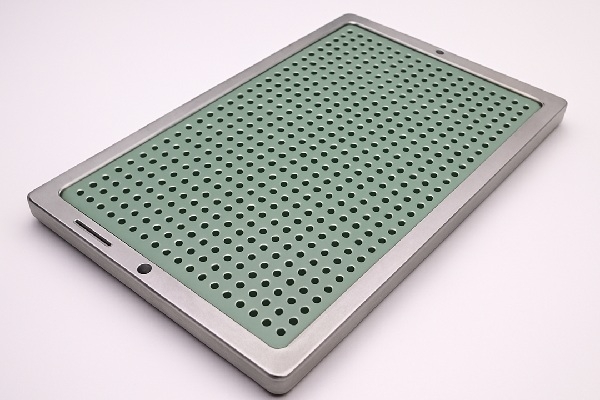

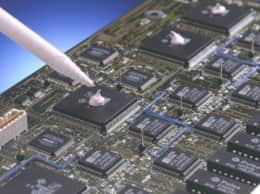

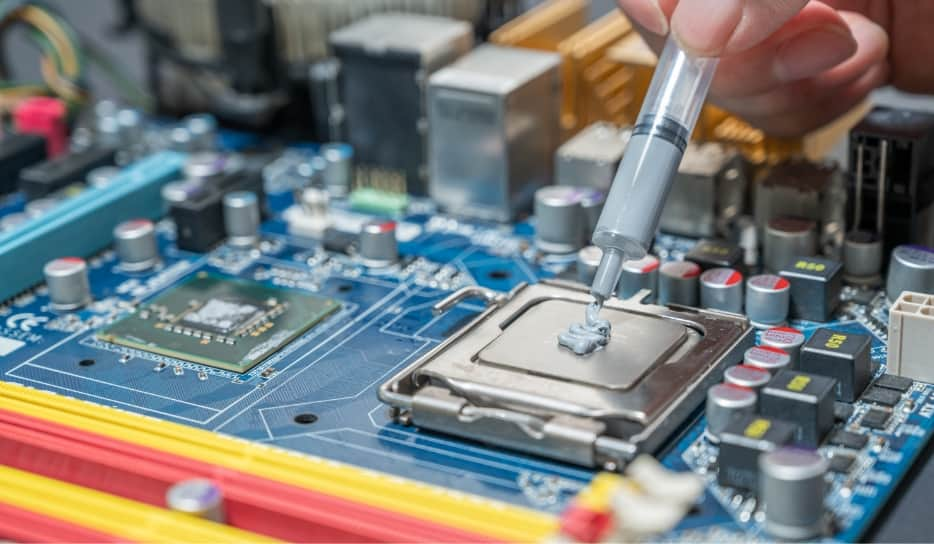

Thermal Interface Material (TIM)

Thermal Interface Materials (TIM) are materials that fill the minute gaps that form between the contact surfaces of components and cases, eliminating the air between them to lower thermal resistance and facilitate the uniform flow of heat. There are many types of TIM, including thermal grease and heat dissipation sheets.

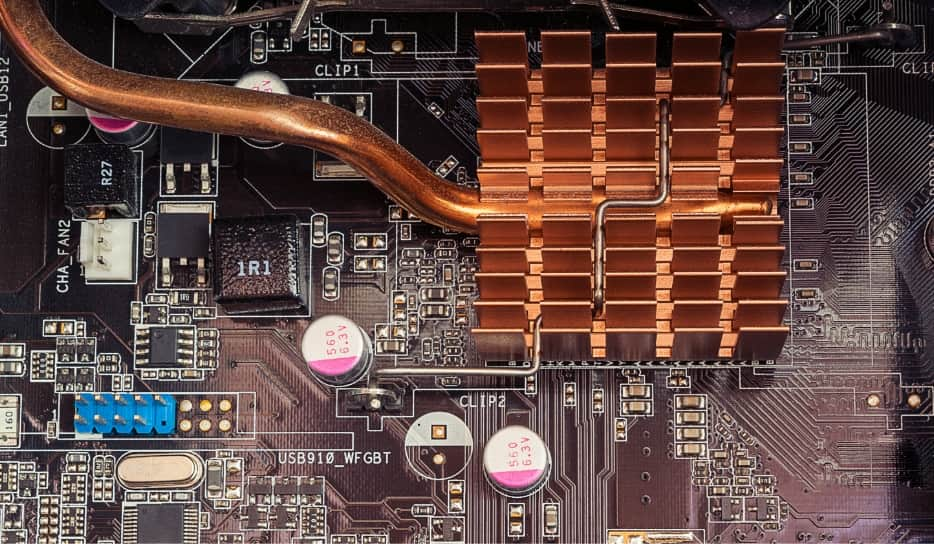

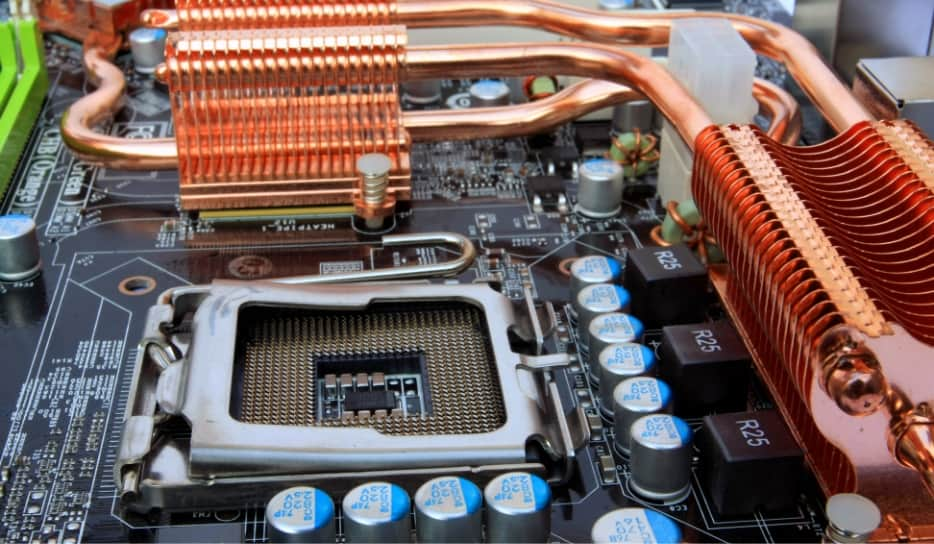

Heat sinks

Heat sinks are a method of thermal management that have seen long use and can be described as heat transfer surface area expansion devices. A heat sink contains multiple fins that physically expand the surface area that dissipates generated heat. This makes it possible to more efficiently move heat between solids objects or between a solid and the atmosphere.

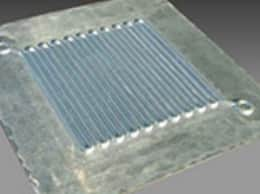

Heat spreaders

A heat spreader is a material that increases the heat transmission surface area and improves the efficiency of heat dissipation in the direction of the case surface. A variety of heat spreaders, such as graphite sheets or metal foil, are used depending on the application and amount of heat generated.

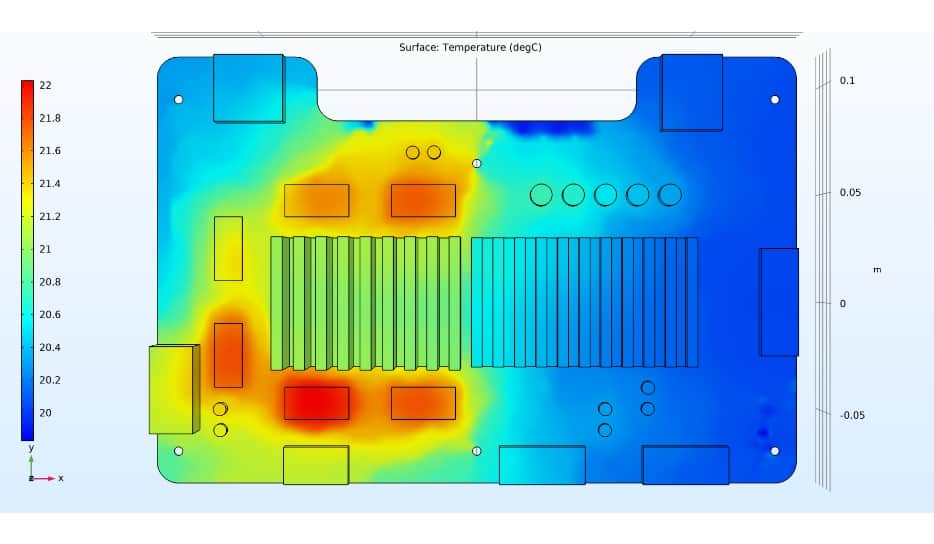

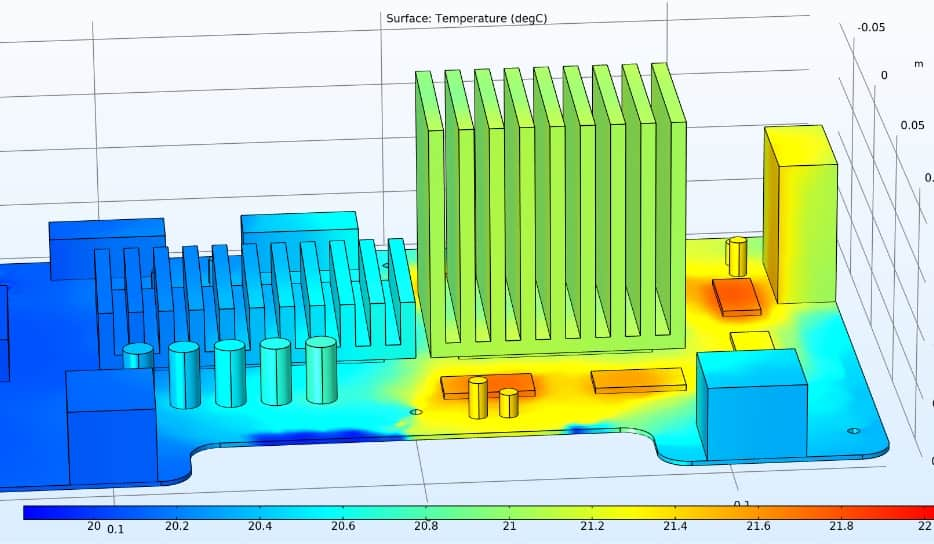

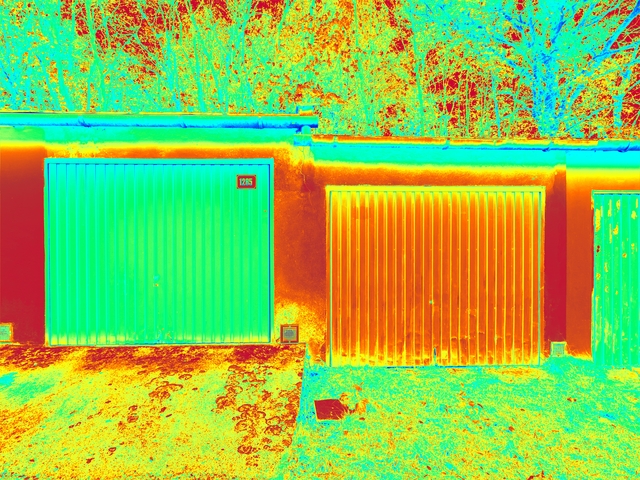

Thermal simulation

In designing heat dissipation for electronic equipment, we numerically analyze the temperature distribution of components such as semiconductors and substrates. We then evaluate the performance and effectiveness of heat dissipation products using thermal simulation.

Thermal design and development

The following is an example of how we apply thermal design and development for our customers.

Solution case studies

Solutions to a heat spot problem on a portable terminal housing

Customer's challenge

The heat generated by the image-processing IC on the board of a mobile device was creating a hot spot on the surface of the outer case.

Our solution

By diffusing the heat using graphite sheets, we eliminated the hot spot on the surface of the outer housing.

POINT

1We listened to and discussed customers' heat dissipation concerns.

POINT

2Through thermal simulation, we verified the effectiveness of heat spreaders and heatsinks.

POINT

3We can offer the optimal products for each application from our extensive range of thermal product lineups.

Thermal management products

See our blog for more information on thermal management products.

FAQ

What happens if thermal management design is not implemented?

Without proper thermal management design, heat cannot be efficiently dissipated, causing the temperature of equipment and devices to increase. This can adversely affect their performance and lifespan.

What types of components are used for thermal management?

Components used in thermal management include heatsinks, thermal interface materials (TIM), heat spreaders, fans, and vapor chambers. Each of these components has distinct characteristics and applications, and they can be combined to achieve optimal thermal management.

What types of TIM exist?

There are various types of TIM, including grease, thermal pads, and phase change materials. Each type has its own distinct characteristics and applications.

How is a heatsink installed?

In most cases, a heatsink is installed in direct contact with the heat-generating electronic component (such as a CPU or GPU). Thermal interface material (TIM) is used to reduce thermal resistance between the heatsink and the electronic component.

Design and Development Processes

If you are interested in utilizing our design or development support, we will guide you through the process. Please contact us if you have any questions.

Click for details Click here for inquiries about thermal management products.

We offer a wide range of products and can provide solutions tailored to each application.