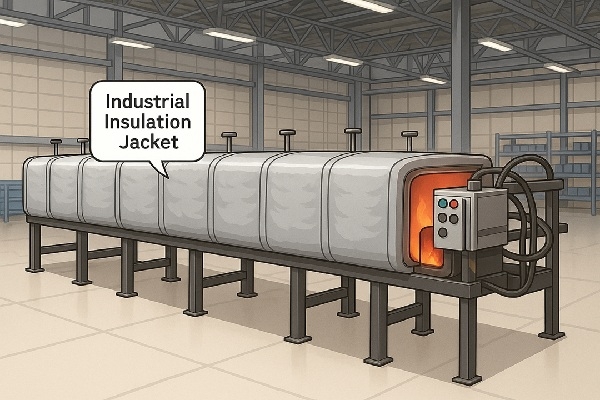

Industrial Insulation Jackets — Improving Energy Efficiency and Working Conditions for Heat Treatment Furnaces

In manufacturing, heat treatment furnaces are widely used for processes such as heating, quenching, and annealing. Operating at high temperatures, these furnaces inevitably release heat from their outer walls, leading to energy loss and deterioration of the surrounding work environment.

An effective solution to these challenges is the Industrial Insulation Jacket. By covering the exterior of a heat treatment furnace with an insulation jacket, heat radiation is reduced, helping to minimize energy loss and improve the working environment.

Key Benefits of Industrial Insulation Jackets

Energy Savings

Industrial Insulation Jackets help prevent heat from escaping the furnace, significantly reducing energy consumption. This leads directly to lower fuel and electricity costs, especially in facilities that operate continuously.

Improved Working Conditions

By lowering the surface temperature of the furnace, these jackets help control the ambient temperature around the equipment. This creates a more comfortable and manageable working environment, contributing to better operational efficiency.

Structure and Materials of Industrial Insulation Jackets

Industrial Insulation Jackets are typically constructed with multiple layers that combine heat resistance, insulation performance, and flexibility. The outer layer is made from heat-resistant fabrics or coated materials, while the inner layers contain high-performance insulation materials. This structure provides excellent thermal insulation while ensuring flexibility and ease of installation.

Additionally, some models offer dustproof or water-repellent features, as well as versions suitable for cleanroom environments, allowing for a wide range of applications.

Ease of Installation and Maintenance

These jackets are designed for easy attachment and removal using Velcro, buckles, or snap buttons. This enables quick and simple removal for maintenance and inspections without disrupting routine operations.

Typical Applications

Various heat treatment furnaces (quenching, annealing, sintering, etc.)

Outer walls of industrial heating equipment

Exterior of thermostatic chambers and drying ovens

Conclusion

Industrial Insulation Jackets are an effective solution for high-temperature equipment such as heat treatment furnaces, providing significant benefits in both energy savings and improved working conditions. To reduce energy costs and enhance workplace comfort, we highly recommend considering the implementation of Industrial Insulation Jackets.

For inquiries about selecting or applying Industrial Insulation Jackets, please feel free to contact Taiyo Wire Cloth. We are ready to provide the optimal solution tailored to your equipment and operational environment.