EMI Shielding

About EMI Shielding

The technology level of wireless communication devices is constantly advancing. 5G is becoming standard and factories and other production sites, as well as society in general, are becoming increasingly IoT-oriented. Electronic control mechanisms are becoming more diverse and complex, as can be seen in the electrification of automobiles. As electrical and electronic devices continue to become smaller and more sophisticated, they are increasingly vulnerable to interference from electromagnetic waves of various frequencies. This can cause communication problems and device malfunctions that not only prevent the devices from performing to their fullest, but can even pose the risk of causing serious accidents. EMI countermeasures are essential to prevent these negative effects of the diffusion of electromagnetic wave noise.

Problems caused by EMI

Electrical and electronic device malfunctions

- The instrumentation used in devices directly related to human life, such as automobiles, airplanes, and other forms of transportation and life-support devices, is becoming increasingly electronic and sophisticated. Electromagnetic noise from smart phones and other devices can affect signal cables and communication devices, preventing electronic controls from functioning correctly. To prevent serious accidents, noise countermeasures must be thoroughly implemented alongside other safety measures. In addition, when new equipment is installed in factories, electromagnetic noise may affect existing devices that have insufficient EMC, causing them to malfunction.

Communication failure and information leakage

- When multiple devices with similar frequency bands are used, such as Wi-Fi and Bluetooth, radio wave interference may occur, resulting in slower communication speeds or interrupted communication. 5G, introduced from 2020, is capable of high-speed, high-capacity communication. Since it uses a different frequency band from the conventional 4G and the amount of information is greater, there is a possibility of unexpected radio wave interference with other electronic devices. In addition, various signals are intermittently emitted as electromagnetic waves from computers and other devices. These electromagnetic waves contain confidential information, so there is a non-zero risk of information leakage if they are received and analyzed.

Health hazards to the human body

- The electromagnetic waves that are normally generated around us do not present the risk of serious damage to human health. X-rays used in hospitals and analysis devices in factories apply safety measures to protect people. In addition, mobile devices such as smartphones are required to comply with radio wave protection guidelines. However, there are biological effects such as heating and stimulation, and there are health risks due to excessive anxiety about electromagnetic radiation.

Addressing customer challenges with EMI shielding expertise

We provide our customers with EMI shielding solutions by offering a wide range of EMI shielding components. We are also continuously engaged in new product development to expand our EMI shielding product lineup. Leveraging our extensive EMI shielding technology and experience, we propose optimal solutions.

EMI Shielding Products

Conductive elastomers

Conductive elastomers are engineered for use in commercial electronic equipment where high degrees of flame retardance and corrosion resistance are needed, and in defense electronic equipment where maximum shielding performance and corrosion resistance are required.

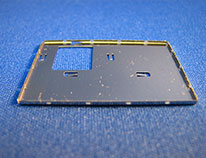

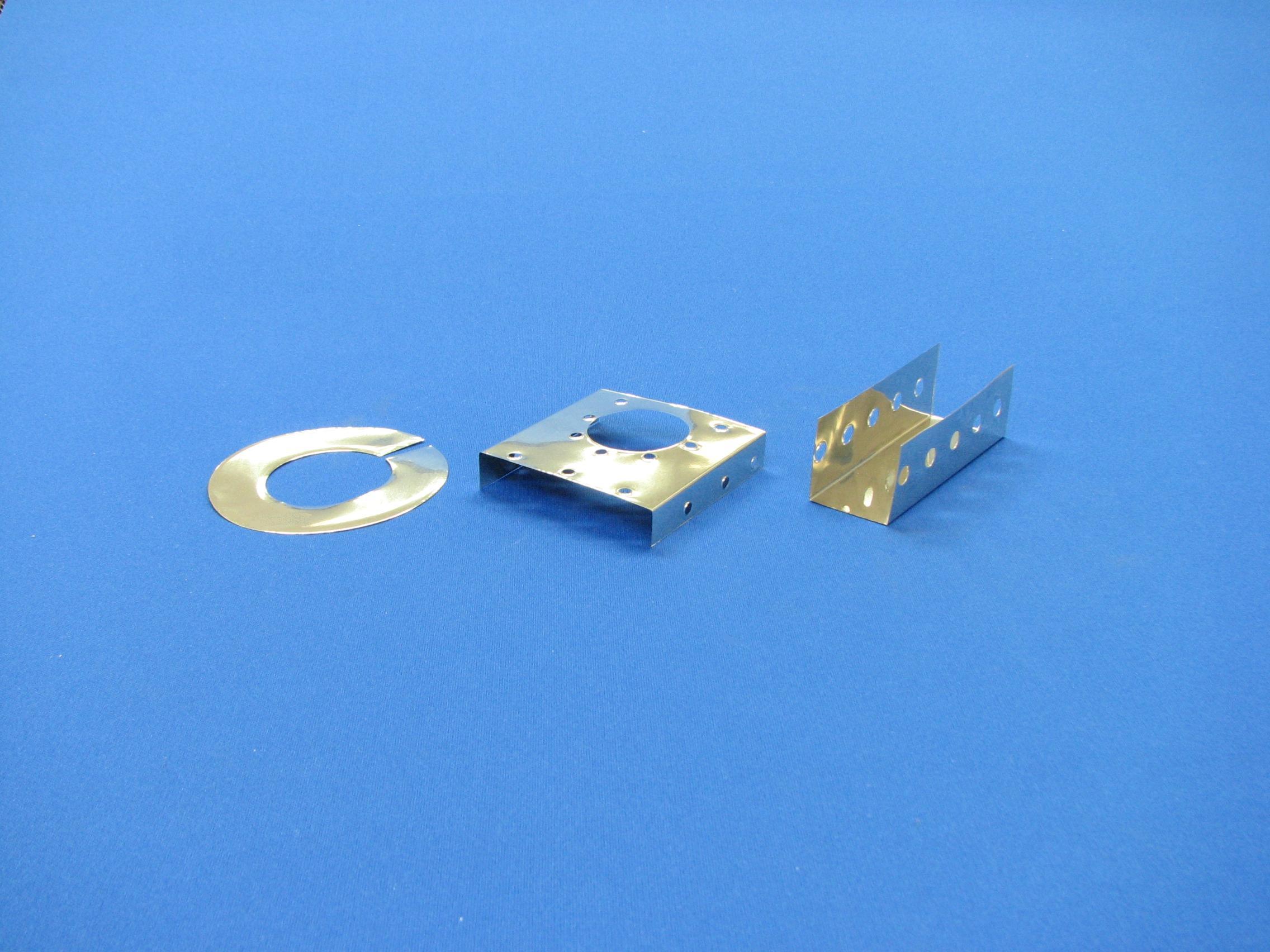

Precision Sheet Metal

TWC provides precision sheet metal as components for electromagnetic wave shielding and heat dissipation. This is commonly used for PCB shield cases, shield covers, shim plates, and shield fingers made of beryllium-copper alloy for electronic device shielding and grounding. We provide custom-made sheets of specific materials and shapes for communication base stations, IoT terminals, and other devices. We can also provide information on how to best mount products in specific design models.

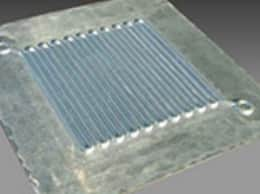

Soft Gasket

These gaskets offer excellent compression-deflection and good shielding effectiveness in a low price fabric-over-foam gasket.

Premier (conductive resin)

Premier is a conductive plastic that achieves conductivity by dispersing nickel-plated graphite fibers within PC-ABS. The raw material of Premier is in pellet form with special embedded carbon fibers (with electroless nickel plating on the surface) uniformly distributed throughout. These pellets include special dispersants to ensure the carbon fibers are evenly distributed within the molding die. The shielding performance of conventional aluminum and magnesium alloys is derived from their conductivity. Premier significantly enhances the attenuation characteristics across the entire frequency range due to its high absorption loss, which is derived from its permeability.

Permalloy tape

Permalloy tape is a magnetic shielding product made of a nickel-based magnetic material in foil form. As a foil, it is highly flexible and can be easily cut with scissors or a cutter. It can be easily wrapped around or attached to various devices, so it easy to apply with optimal forming. Its main advantages are its extreme ease of installation and that it can provide magnetic shielding quickly and at low cost.

Fine expanded metals

This expanded metals have high-precision characteristics.

Shield fingers

This product provides high levels of EMI shielding effectiveness with spring-finger wiping and low closure force properties.

Radio wave absorber MICROSOBER®

Radio wave absorber MICROSOBER® provides a clean electromagnetic environment in a variety of situations, from small electronic devices to building structures.

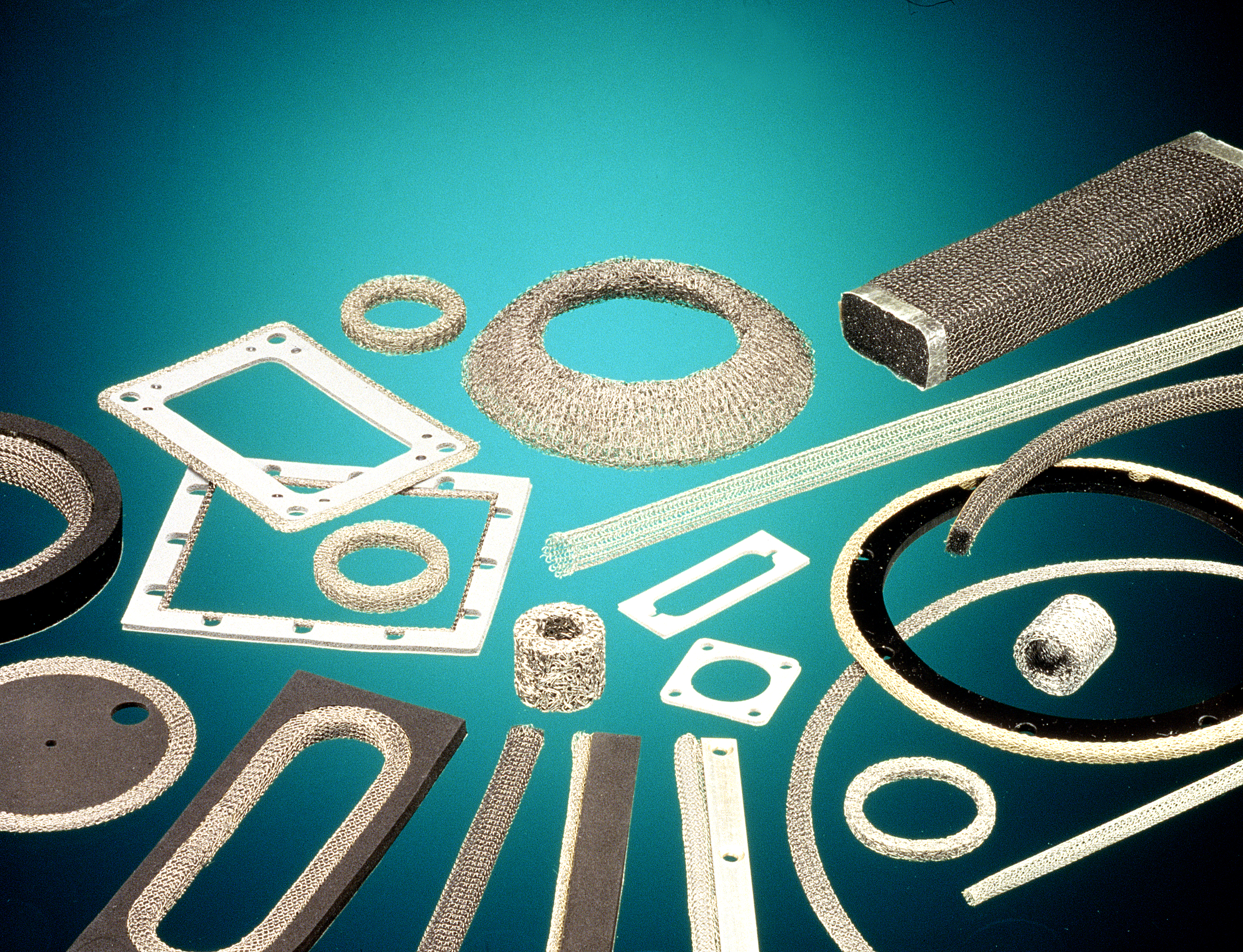

Shield gasket

Metal mesh provides EMI shielding, while neoprene or silicone ensures an air and watertight seal.

Examples of EMI shielding development

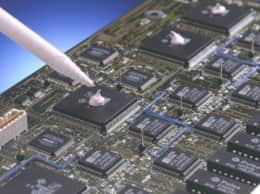

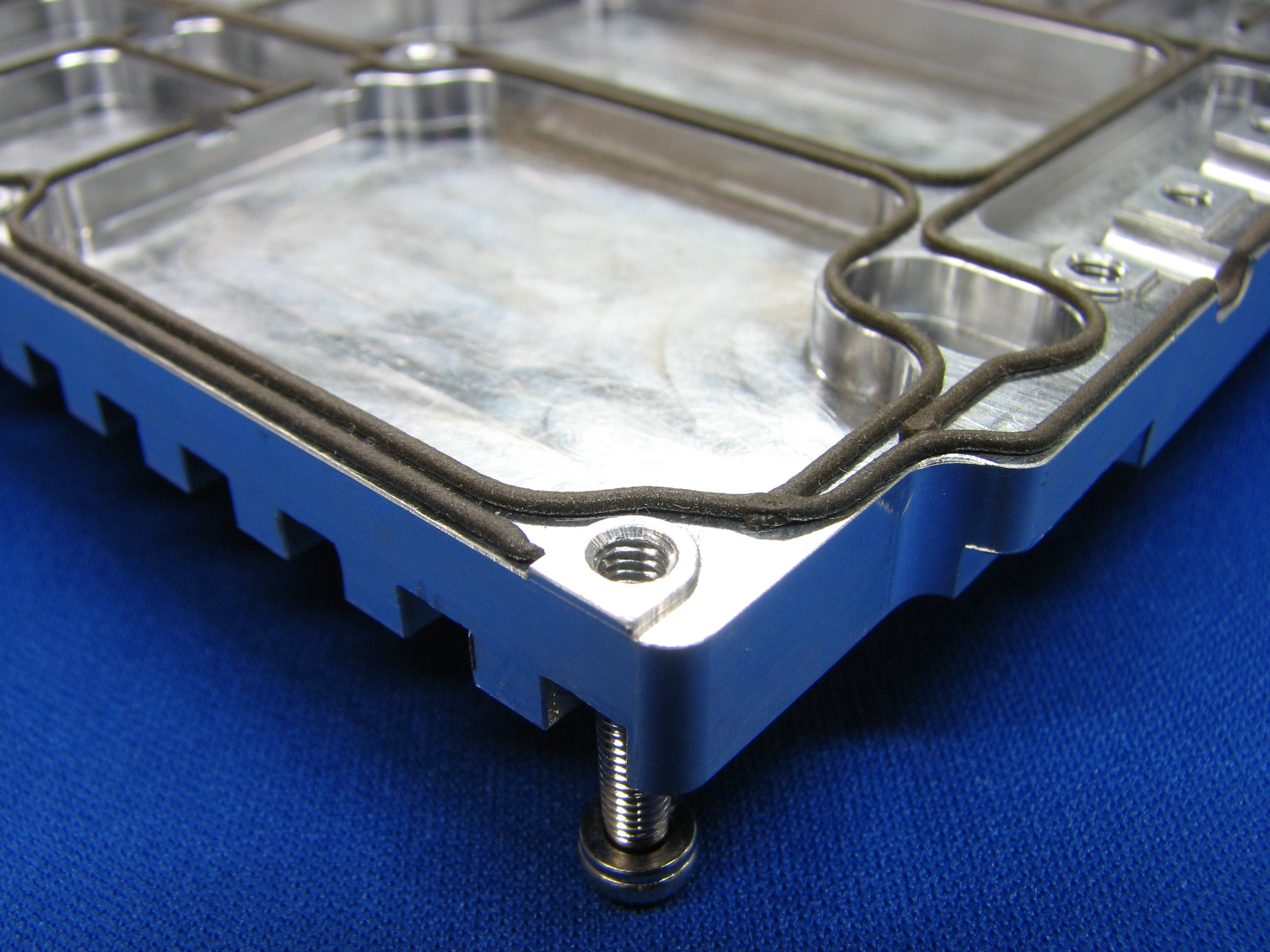

Below is just one of the many real-world applications of our EMI shielding gaskets (Cho-Form).

Application

EMI shielding alongside miniaturization and weight reduction of electronic enclosures.

Customer's Challenge

The customer was trying to miniaturize and reduce the weight of a machined aluminum case. They were using a conductive elastomer fitted into the grooves of the case's flange and ribs, which was hindering the miniaturization and weight reduction.

Our solution

By using Cho-Form, a conductive elastomer gasket, they were able to save space on the ribs of the case. Cho-Form is automatically dispensed onto the flange and ribs of the case. It is strongly adhesive, so it can attach firmly to thin ribs, which allows for reduced rib thickness to save space.

POINT

1We propose tailored solutions to address customer challenges.

POINT

2We can propose the best shielding technology and components from our wide range of products.

EMI countermeasures

EMI countermeasures are an essential part of preventing the effects of electromagnetic noise. Electromagnetic waves leak from various parts of electrical and electronic devices.

- Housing: electromagnetic waves leak out of devices, depending on the material and thickness of the case

- Openings: electromagnetic waves leak from vents, access panels, etc.

- Cables: signal transmission cables and other cables can become antennas and emit electromagnetic waves

The electromagnetic noise can also be categorized into the following categories depending on how it propagates.

- Conduction noise: noise that propagates through power cables, LAN cables, etc.

- Radiation noise: noise that propagates through the air

In other words, EMI countermeasures must address not only the sources and transmission paths of conduction noise, but also the spread of radiation noise.

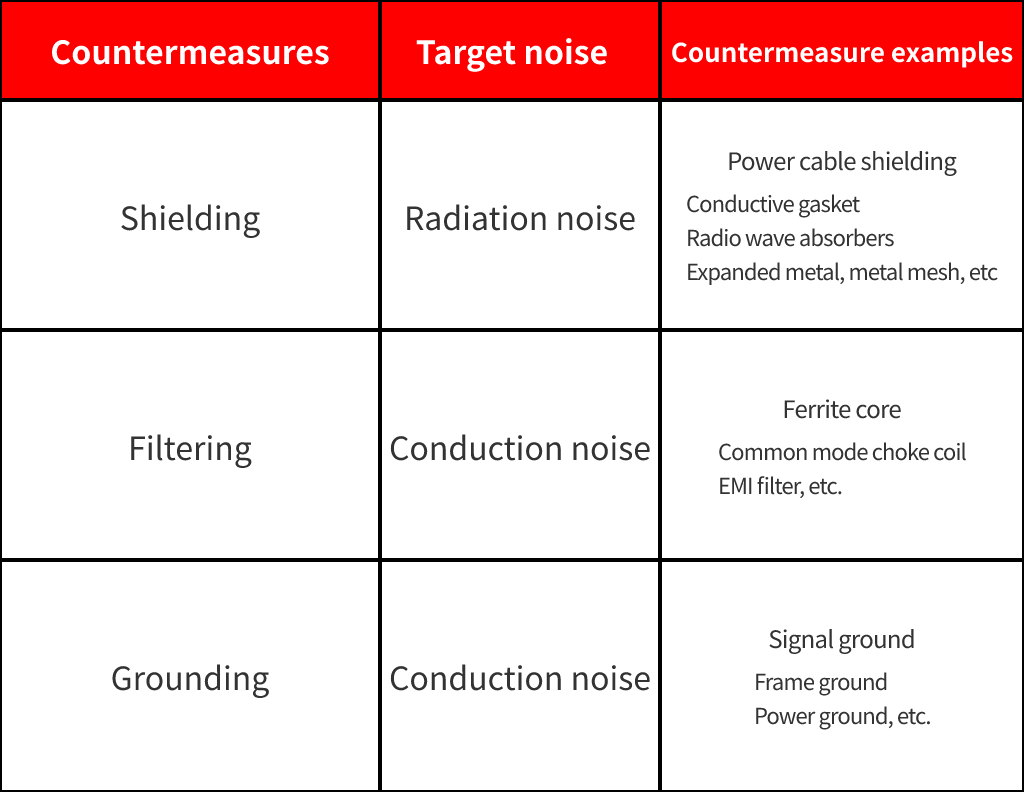

EMI countermeasure examples

EMI countermeasures take a variety of forms. The table below shows some typical examples and what they are used for.

Power and communication cables can both serve as transmission paths for noise and generate radiation noise themselves. Therefore, it is essential to take measures based not only on physical protection of the wires but also on electromagnetic wave shielding measures.

Design and Development Process

If you are interested in utilizing our design or development support, we will guide you through the process. Please contact us if you have any questions.

EMI shielding inquiries

We offer a wide range of products and can provide solutions tailored to each application.