Metal Processing

Metal processing Overview

We offer a range of metal processsing technologies.

Machining

Stamping

Stamping involves the use of molds for processing, allowing high-precision products to be mass-produced. The processing speed is fast, resulting in high production efficiency, but there are initial costs associated with mold production. From automotive parts to electronic components and daily necessities, stamping processes are used to manufacture metal products, from the cutting-edge industries to the mundane.

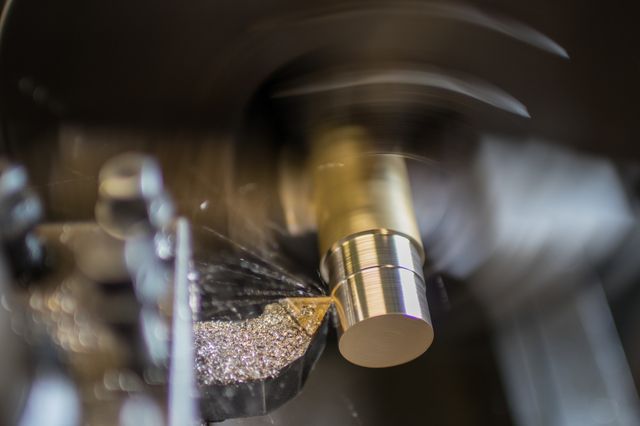

Numerical control (NC) machining

In numerical control (NC) machining, processing is automatically controlled based on numerical information, ensuring stable processing accuracy. This approach both shortens processing time and improves production efficiency while reducing labor costs.

Laser processing

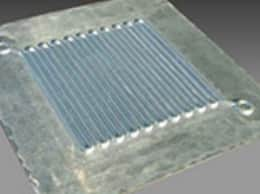

CO2 lasers, YAG lasers, fiber lasers, and other types are all used for processing, with the appropriate laser selected according to the application. The advantages of laser processing include the ability to perform complex and fine processing, high processing freedom, minimal deformation or cracking of materials, high working efficiency, and no need for molds.

Welding

Welding processes include arc welding, TIG welding, spot welding, laser welding, brazing, and more. The optimal process depends on the actual application, including the shape, size, and material of the metal workpiece. For example, laser welding is widely used for applications where high precision in welding position or high appearance requirements for welded joints are needed, as it involves melting the components to be joined at high temperatures.

Die casting

Perforated plate

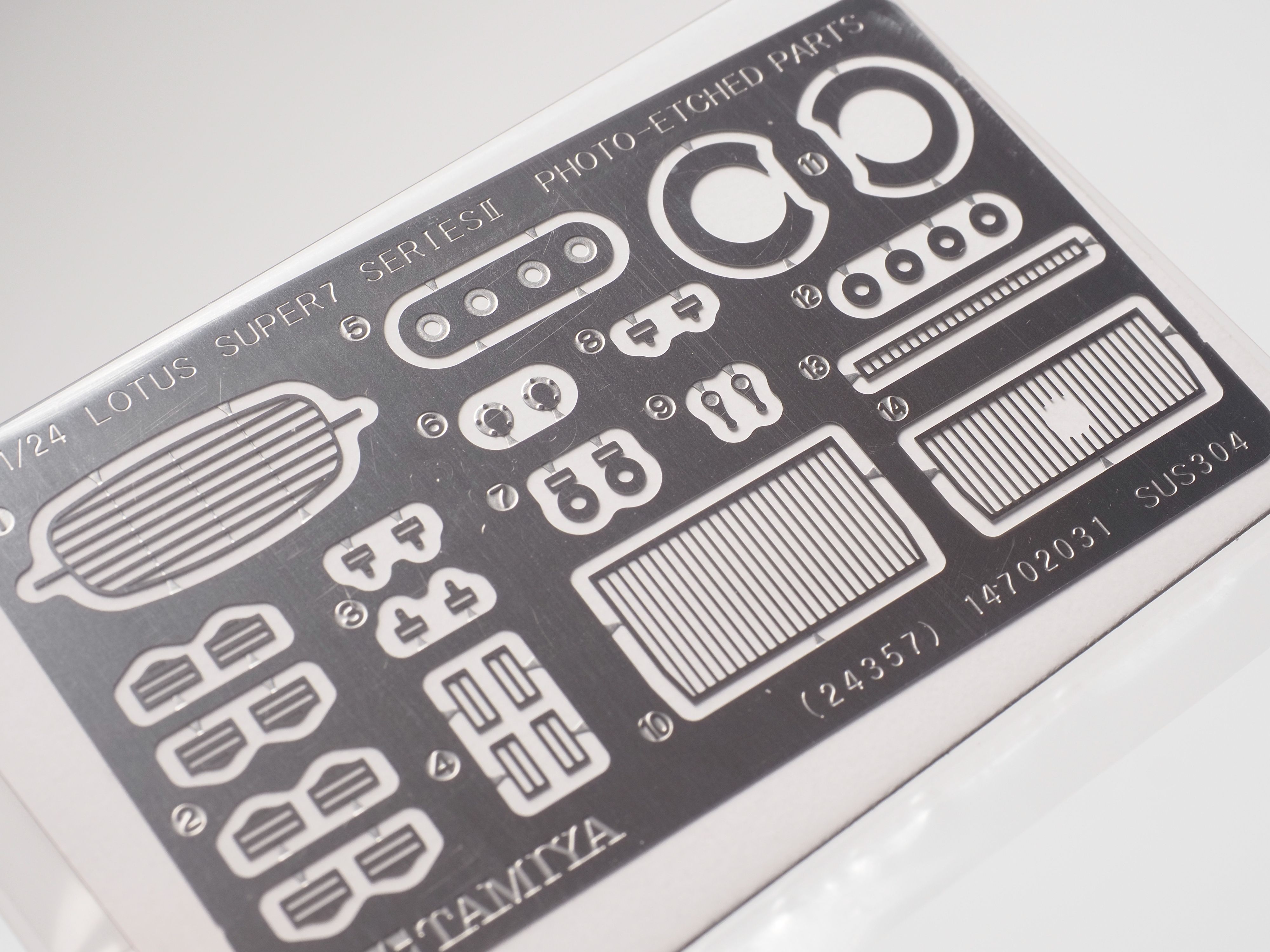

Etching processing

From material selection to processing techniques, we can accommodate all your needs

Materials that can be processed:

Stainless steel

Iron

Aluminum

Copper

Nickel

Chromium-nickel-iron alloy

Monel

We can also accommodate other materials not mentioned above. Please feel free to inquire about your specific needs.

We will work to understand your challenges, and then employ the technology and expertise of our QCD team, along with the capabilities of our 250 partner factories, to provide creative solutions and proposals. We can propose solutions to improve production efficiency, enhance quality, stabilize your supply chain, implement unmanned production, and automate production processes, utilizing our deep technological resources.

Applications of metal processed products

In factory production lines

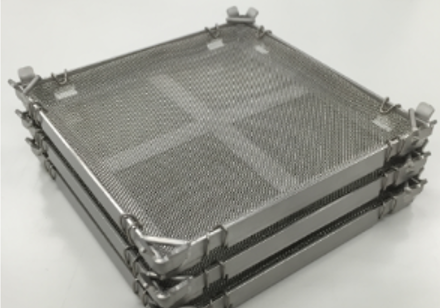

Mesh filters installed in pipelines, baskets used in cleaning processes, trays for heat treatment processes, and more. We offer custom designs based on our customers’ specific applications. Please consult with us if you are facing challenges in your production process.

Components for customer products

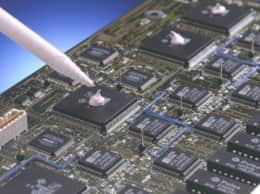

This includes metal components, EMI shielding products, and thermal products for electronic devices such as appliances and industrial machinery. As shown in the image, etched components are utilized in microphones and speakers used in audio equipment. We can support applications ranging from small-scale trials to mass production. If you have any questions about product design, please feel free to consult with us at any time.

POINT

1We help our customers improve productivity, automation, and quality through our products and technologies.

POINT

2By providing mesh, thermal, and EMI shielding technologies, we enhance the performance and reliability of our customers' products.

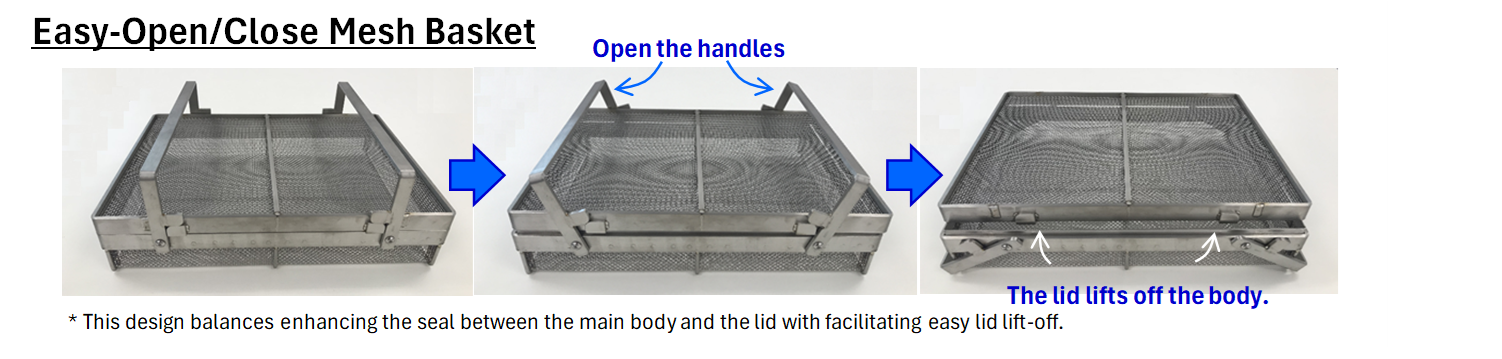

Metal processing case study—Mesh baskets

A metal mesh basket (body & lid) that is easy to open and close (used for cleaning, drying, degreasing, etc.)

When the handle is closed, the lid and body of the basket are securely fixed together. When the handle is opened, the lid pops up.

Advantages:

The lid can be easily attached and removed.

The clearance between the body and lid is very small, ensuring very smooth seams.

The lid and basket are separate, but when the handle is closed, they form a single unit. When the handle is opened, the lid pops out.

Design and Development Process

If you are interested in utilizing our design or development support, we will guide you through the process. Please contact us if you have any questions.

Click here for metal processing inquiries.

We offer a wide range of products and can provide solutions tailored to each application.