FGHP: Revolutionizing Heat Dissipation for SiC Modules in EV Inverters

As electric vehicles (EVs) continue to advance, the power density of SiC (silicon carbide) modules used in inverters is rapidly increasing—resulting in greater heat generation. Traditional heat dissipation methods using copper heat spreaders are reaching their limits in handling such high heat flux, and further improvements in cooling efficiency are essential.

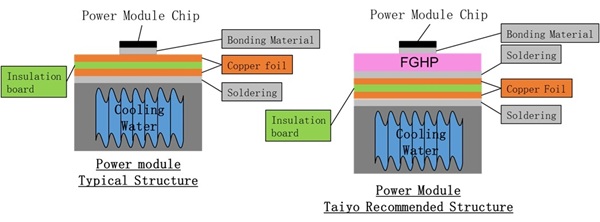

Our proposed solution is a new thermal structure featuring a high-performance vapor chamber called FGHP (Fine Grid Heat Pipe). Despite its thin profile, FGHP is a powerful vapor chamber that allows SiC devices to be mounted directly on its surface, with circuits formed above. The heat generated by the SiC devices is instantly spread as the working fluid inside the FGHP repeatedly evaporates and condenses. This significantly reduces heat density and efficiently transfers the heat to a water-cooled heat sink—achieving exceptional overall thermal performance.

What stands out is its thermal efficiency. Our evaluations show that FGHP offers up to 60% improvement in heat dissipation compared to conventional copper structures. This high efficiency also enables miniaturization and weight reduction of the module.

Despite being just 1.8–2.2 mm thick, FGHP offers an impressive in-plane thermal conductivity of 4,000 W/m·K. This makes it an ideal solution for EV inverter modules, which demand advanced thermal management in limited space.

The illustration below compares the conventional structure with our proposed design.

FGHP enables circuit formation directly on its surface and allows direct bonding of SiC devices. This structure leverages superior heat-spreading capability to greatly reduce thermal density and enable efficient cooling. While conventional vapor chambers may deform under the extreme thermal loads of SiC devices, FGHP maintains stable performance even in such high-heat-load applications—thanks to its robust structure.

Thermal challenges associated with the high-temperature operation of SiC devices are critical to advancing EV performance. Our innovative solution, combining high heat-spreading capability and structural strength, supports the next generation of mobility.