Features and Benefits of Precision Gear Pumps for Slurry Supply in Coating Processes

In the manufacturing of lithium-ion batteries and electronic components, it is essential to supply materials such as slurry, paste, and other highly viscous liquids with consistency and precision. In particular, coating processes are highly sensitive to even minor fluctuations in flow rate or pulsation, which can significantly impact product quality. For this reason, pumps capable of precise flow control are indispensable — and precision gear pumps are gaining considerable attention in this area.

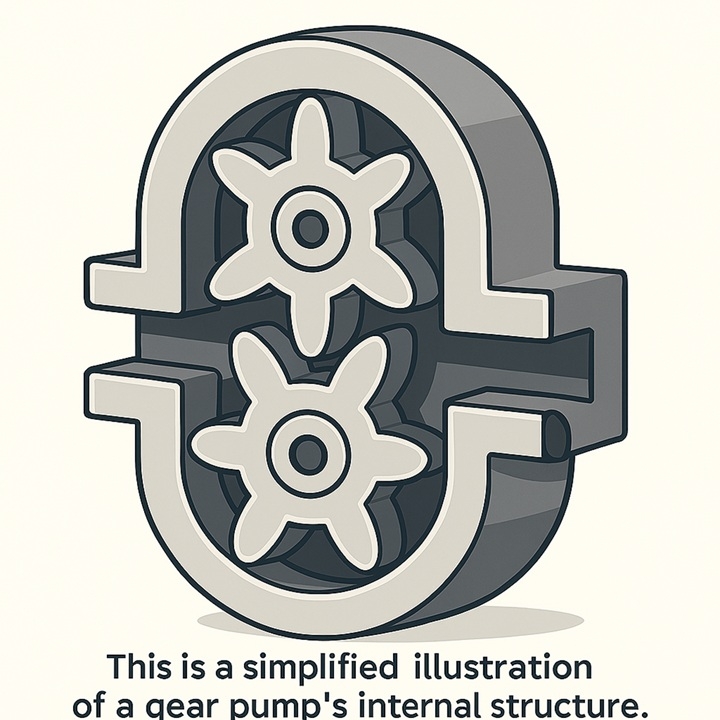

Precision gear pumps utilize the rotation of two intermeshing gears to transfer liquids, achieving both stable flow and high discharge accuracy. They demonstrate excellent performance even with highly viscous materials like slurry, where uniform supply is critical. Their ability to maintain stable discharge at low flow rates makes them especially suitable for processes such as fine coating and thin film formation.

Moreover, the precisely machined gears and tight gap control minimize internal leakage, ensuring efficient transfer. This minimizes risks such as component separation or agglomeration within the slurry, contributing to consistent coating quality. The use of wear-resistant materials such as metal and ceramics also helps to mitigate abrasion caused by fine particles in the slurry.

Compared to conventional pumps, precision gear pumps offer the distinct advantage of exceptionally low pulsation. Reduced pulsation directly translates to more uniform coating thickness and stable film surfaces, enabling the production of higher-quality products.

Given these advantages, precision gear pumps are the ideal choice for applications that demand consistency and stability, such as electrode coating for lithium-ion batteries and the coating of electronic components. As manufacturers seek to stabilize production, improve yields, and ensure product uniformity, the use of precision gear pumps is expected to expand further.

For Gear Pump Inquiries, Contact Taiyo Wire Cloth

At Taiyo Wire Cloth, we provide tailored proposals for precision gear pumps. If you are facing challenges in supplying slurry or paste, please feel free to contact us. We are ready to offer optimal solutions that meet your specific needs and requirements.