Resin Processing

Resin processing

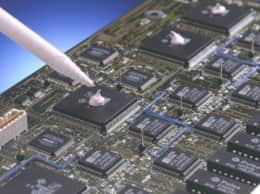

Insert molding

Insert molding is a technique that integrates resin products with different materials, such as metal mesh, to enhance the functionality and durability of products. For some filters, insert molding is used in the resin molding process to produce filters that combine metal mesh with resin, resulting in high filtration efficiency and increased strength.

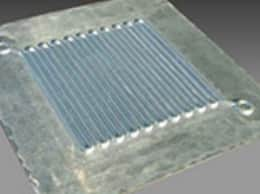

Conductive plastic

Conductive plastic, used in shielding cases for electronic substrates, combines the shielding performance of aluminum boxes with the lightweight characteristics of plastic. Conductive plastic pellets contain conductive fillers that fully penetrate every corner of the case during injection molding, ensuring the case's conductivity. Compared to metal, conductive plastic offers lighter weights and greater design freedom, making it increasingly in demand in areas requiring lightweight solutions, such as mobile devices like smartphones and laptops.