Coating & Surface

Coating and surface treatment

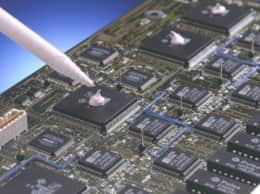

Surface treatments can be used to give materials various new functions. For example, treating the surface of a product can improve wear resistance, electrical characteristics, slipperiness, cleanability, or adhesion prevention. Our surface treatment technologies have applications in process improvement for production sites, and may offer solutions to your problems.

Production site issue

Application examples

Addressing Customer Challenges with Coating & Surface Treatment Expertise

We offer a variety of specialized coatings and surface treatments to help solve manufacturing challenges. Leveraging our extensive expertise, we can provide optimal solutions to improve slipperiness, prevent adhesion, extend lifespan, and enhance cleanability at your worksite.

Functional enhancement through surface treatment

We offer a variety of surface treatments, some of which are detailed below.

SR-C Treatment

Purpose: Enhances slipperiness, prevents adhesion, improves demolding performance, and increases durability (for metals).

Target materials: Metals, resins, ceramics.

Micro Fluorine Layer Thin Coating

PPurpose: Enhances molding release and slipperiness with its thin layer (approximately 1 μm or less), suitable for precision molds and tools

Target Materials: Metals and resins.

Anti-Static Fluorine Coating

Purpose: Maintains slipperiness while preventing adhesion due to static electricity

Target Materials: Metals.

Superhydrophilic Coating

Purpose: Enhances cleanability by enabling water to penetrate between the base material and dirt (such as paste-like substances), facilitating removal.

Target Materials: Metals.

Blasting

Purpose: Deburring, cleaning, addition of anchor effect.

Target Materials: Metals and resins.

Shot peening Treatment

Purpose: Improves surface strength and prevents stress corrosion.

Target Materials: Metals.

Electroplating and Electroforming

Material Types: Nickel, ogld, platinum, fluororesin composites.

Thermal Spraying

Target materials: YSZ (Yttria Stabilized Zirconia), alumina, specific materials for preventing adhesion

Gas Phase Synthesis

Methods: CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), TiC (Titanium Carbide), TiN (Titanium Nitride), DLC (Diamond-Like Carbon).

Molybdenum Disulfide Treatment

Purpose: Spraying treatment for ultra-low wear and high slipperiness, prevents screw seizure.

Titanium Oxide Treatment

Purpose: Forms a high-adhesion strength titanium oxide film without using sprays or binders.

Coating and surface treatment solutions

We address manufacturing process challenges for our clients with our specialized coating and surface treatment solutions.

Application

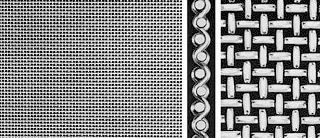

The customer needed to prevent powder adhesion in their manufacturing process.

Customer challenge

Mesh screening is used in the production process. Due to the properties of the powder, it was accumulated and retained on the mesh, negatively impacting production efficiency.

Our Solution

It was not possible to use of coatings because of the potential risk of foreign materials from the coating layer detaching. We recommended surface treatments that do not involve a coating layer. We selected and proposed the most suitable surface treatment to improve slipperiness and prevent powder retention.

POINT

1Based on customer needs and thorough evaluation, we proposed the most appropriate surface treatment plan. In this case, we enhanced the slipperiness of the mesh through surface treatment without coating, which effectively mitigated the issue of powder retention.

POINT

2Addressing the customer's production challenges, we propose solutions from various perspectives. Beyond just coatings and surface treatments, we also offered technical advice on mesh specifications to further enhance production outcomes.

FAQ

What materials can coating and surface treatment be used for?

We can apply coatings and surface treatments to metals, resins, and glass. There are many types of coating available, and we can propose options tailored to each specific application.

Is it possible to perform coating on equipment or fixtures used in a factory?

Yes, it is possible. We offer the optimal coating based on the purpose of the coating, as well as the size and material of the physical product.

What are the benefits of coating and surface treatment for products?

Coatings and surface treatments can provide various functions. For example, they can improve corrosion resistance, enhance surface hardness (wear resistance), improve slipperiness, enhance cleanability, provide waterproofing, and improve oil and anti-sticking properties.

One example is the use of DLC (Diamond-Like Carbon) coatings, which improve wear resistance and extend the lifespan of molds and tools, capabilities not possible with the original untreated surface.

Design and Development Processes

If you are interested in utilizing our design or development support, we will guide you through the process. Please contact us if you have any questions.

Click here for inquiries about surface treatment.

We offer a wide range of products and can provide solutions tailored to each application.