Latest order |

Arrange in the oldest order

Slot Dies: Essential for High-Precision Coating

Heat-Resistant Tags That Withstand High Temperatures — Reliable Management of QR Codes and Barcodes

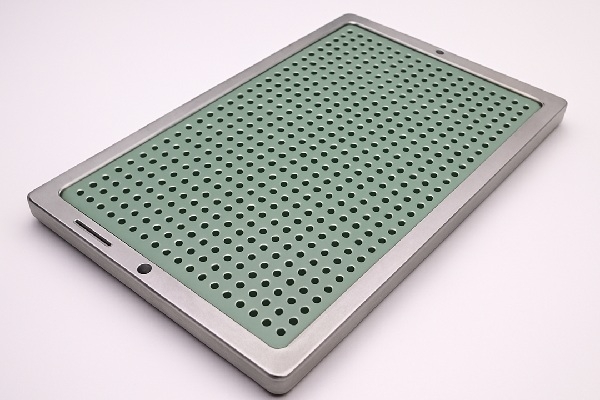

Holding Plates – Essential Tools for Fine Electronic Component Manufacturing

Metal Pins

Industrial Insulation Jackets

Drum-Type Screen Mesh

Prototyping and Small-Lot Resin Molding with 3D Printing

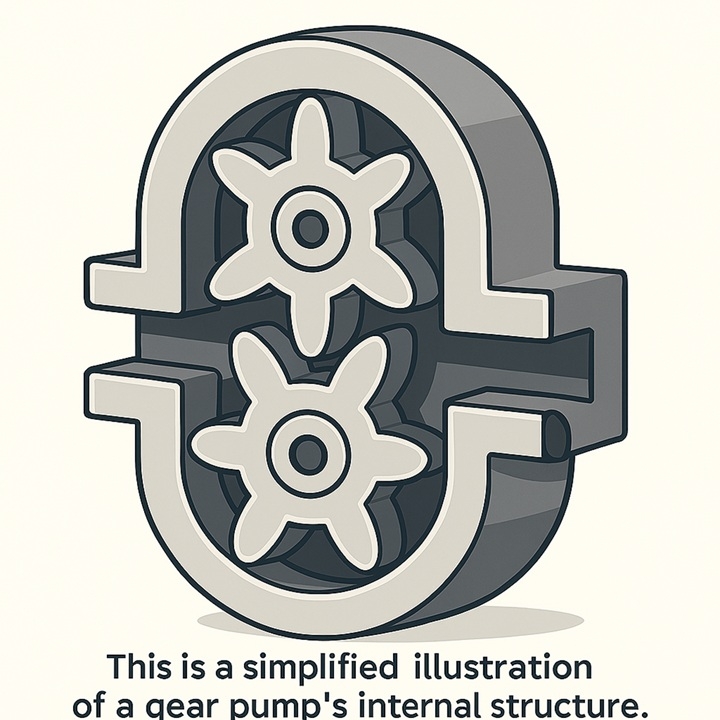

Features and Benefits of Precision Gear Pumps for Slurry Supply in Coating Processes

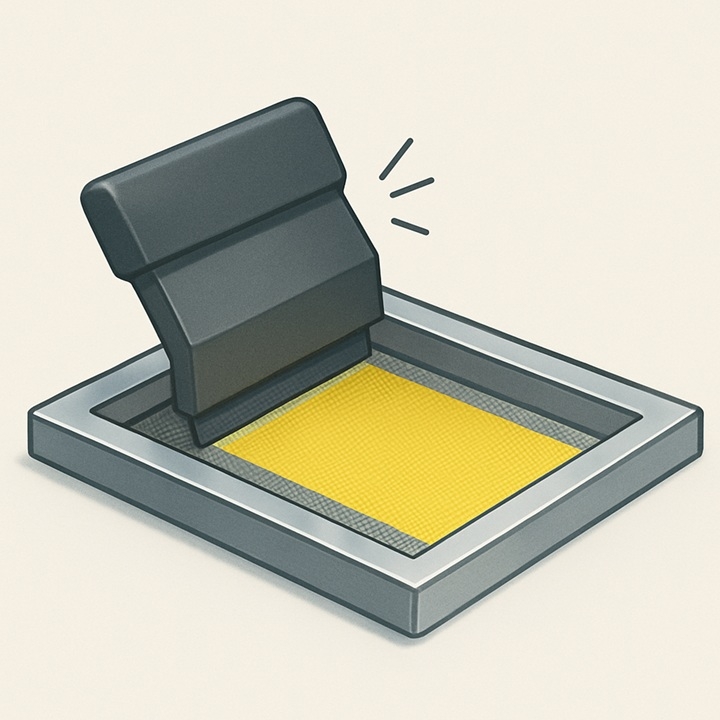

Mesh for Screen Printing

Latest news

Category

Label