Semiconductor Manufacturing and EMI Shielding

Semiconductor manufacturing equipment is demonstrating extremely high growth in the modern technology industry, driven by the increasing demand for semiconductor devices. Semiconductors are indispensable technologies in various industries, including smartphones, computers, automobiles, artificial intelligence, and cloud computing. The growth and advancement of these industries are rapidly increasing the demand for semiconductors, which in turn is driving up the demand for semiconductor manufacturing equipment.

Key Semiconductor Manufacturing Equipment

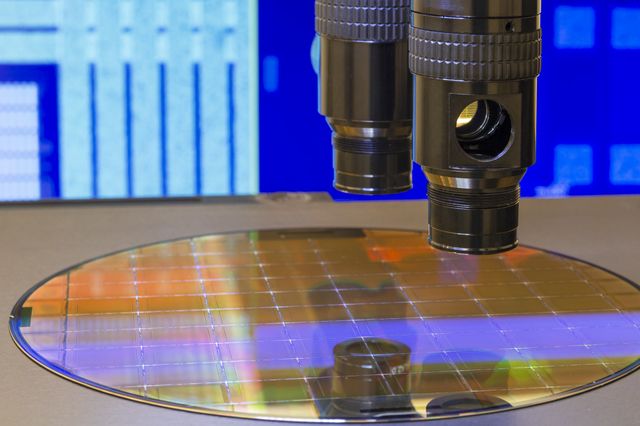

Semiconductor manufacturing equipment is used to execute the semiconductor manufacturing process. There is a wide variety of equipment, but the main equipment for major processes includes etching equipment, CVD equipment, exposure equipment, and testers.

Etching Equipment

Used to remove films or patterns on semiconductor wafers. By using chemical reactions or plasma, specific areas of the wafer surface are selectively removed.

CVD Equipment (Chemical Vapor Deposition Equipment)

Used to grow thin films on semiconductor wafers using gaseous precursors. Precursor gases are supplied to the wafer surface, and films are formed through chemical reactions.

Exposure Equipment

Used to form fine circuit patterns on semiconductor wafers. Light is used to transfer patterns from a mask onto the wafer.

Testers

Used to test the functionality and quality of manufactured semiconductor devices. They perform signal transmission and reception, measure electrical characteristics, and conduct operational tests.15:54:48

The Importance of EMI Shielding

With the advancement of the latest technologies, there is a growing demand for finer and higher-performance semiconductors. Accordingly, the development of more advanced manufacturing equipment for each manufacturing process is required. To ensure the proper operation of these semiconductor manufacturing equipment, EMI (Electromagnetic Interference) shielding design, which prevents electromagnetic waves from causing interference, is indispensable.

EMI countermeasure examples

EMI countermeasures take a variety of forms, and the following are some typical examples.

| Countermeasures | Target noise | Countermeasure examples |

|---|---|---|

| Shielding | Radiation Noise | Power cable shielding Conductive gasket Radio wave absorbers Expanded metal, metal mesh, etc. |

| Filtering | Conduction noise | Ferrite core Common mode choke coil EMI filter, etc. |

| Grounding | Conduction noise | Signal ground Frame ground Power ground, etc. |

Power cables and communication cables not only serve as transmission paths for noise, but can also generate radiation noise. Therefore, it is essential to take measures based not only on physical protection of the wires but also on electromagnetic wave shielding measures.

Types of EMI shielding

In order to increase the noise attenuation effect in EMI shielding, it is ideal to surround the noise source with a material that has high conductivity and magnetic permeability without any gaps. A metal plate as a housing material can be expected to have a high EMI shielding effect. In actual device designs, EMI shielding using only a metal housing is difficult due to gaps in the enclosure (electrical discontinuity between the case and the cover), openings for ventilation, protruding cables, and other factors.

For this reason, the following materials are used for EMI shielding depending on the location of use and purpose.

| Shielding materials | Outline |

|---|---|

| Conductive elastomer | Sheet or string EMI shielding gasket made of silicone with added conductive filler |

| Soft shield | EMI shielding gasket consisting of a conductive fabric (nickel-plated nylon material) covering a urethane sponge core |

| Shield fingers | Grounding/EMI shielding product group using beryllium copper alloy as a material with particularly excellent elastic performance |

| Shield line | EMI shielding gasket made of special metal wire cloth formed into a string shape |

| Cho-Form (FIP Gasket) | Conductive silicone gasket automatically mounted on a metal or plastic housing |

| Precision expanded metal | Precision expanded metal for EMI shielding in openings where ventilation and visibility are required |

| Shield honeycomb | Honeycomb-shaped EMI shielding product group used in openings that require high air permeability |

| Conductive tape | Metal foil (copper or aluminum) tape lined with conductive pressure sensitive adhesive |

| Conductive plastic | Conductive plastic that has conductive properties made by dispersing nickel-plated graphite fibers in PC-ABS |

| Radio wave absorbers | EMI countermeasure materials that absorb electromagnetic noise. There are two types of electromagnetic wave absorbers based on different principles: suppression and resonance. |

| Permalloy tape | A magnetic shield product made of magnetic material, mainly nickel alloy, in the form of a foil |

| Shield can | Precision sheet metal parts for EMI shielding |

*Products handled by Taiyo Wire Cloth

Contact Taiyo Wire Cloth Co., Ltd. for EMI shielding

There are various types of EMI shielding, and it is essential to select the right material for the operating environment and to verify the effectiveness of EMI shielding in advance. Taiyo Wire Cloth Co., Ltd. handles a variety of EMI shielding product group such as gaskets, conductive elastomers, soft gaskets, and shield fingers.

For more information on various EMI shielding products, please visit our product pages.