LiDAR and EMI Shielding

LiDAR (Light Detection and Ranging)

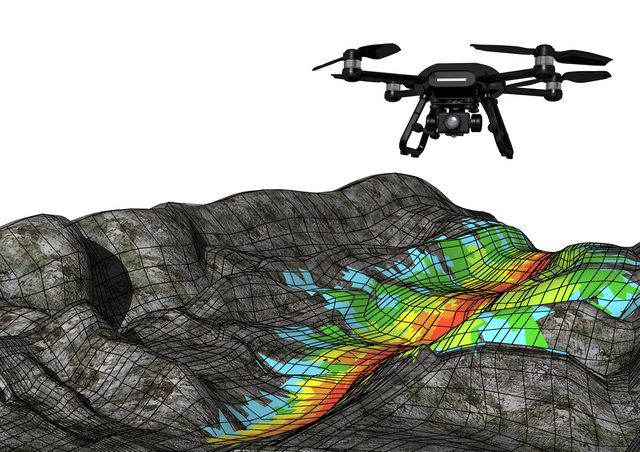

LiDAR (Light Detection and Ranging) is a device expected to see expanding use in autonomous driving for vehicles, as well as in 3D surveying for construction and industrial applications. LiDAR uses infrared laser beam sensing technology. By measuring the time it takes for the laser light emitted from the LiDAR to reflect off an object and return, it calculates the distance and direction to the obstacle. LiDAR can collect extensive data about the surrounding environment, create 3D maps, and accurately determine the position and shape of objects. Generally, LiDAR uses near-infrared light, which is outside the range of visible light.

Furthermore, the LiDAR market is expected to grow in the future. The increasing demand for autonomous driving technology and Advanced Driver Assistance Systems (ADAS) in the automotive industry is driving the demand for LiDAR sensors. LiDAR is also being utilized in fields such as construction and surveying, agriculture, manufacturing, and robotics. Additionally, advancements in technology and cost reductions are anticipated to accelerate the widespread adoption of LiDAR.

To ensure the proper operation of LiDAR, product design that takes EMI (Electromagnetic Interference) countermeasures into account is essential. An EMI design that prevents electromagnetic waves from interfering is required to ensure that critical components of LiDAR devices (such as the emission circuit, reception circuit, and transceiver) operate accurately without being affected by electromagnetic waves.

EMI countermeasure examples

EMI countermeasures take a variety of forms, and the following are some typical examples.

| Countermeasures | Target noise | Countermeasure examples |

|---|---|---|

| Shielding | Radiation Noise | Power cable shielding Conductive gasket Radio wave absorbers Expanded metal, metal mesh, etc. |

| Filtering | Conduction noise | Ferrite core Common mode choke coil EMI filter, etc. |

| Grounding | Conduction noise | Signal ground Frame ground Power ground, etc. |

Types of EMI shielding

In order to increase the noise attenuation effect in EMI shielding, it is ideal to surround the noise source with a material that has high conductivity and magnetic permeability without any gaps. A metal plate as a housing material can be expected to have a high EMI shielding effect. In actual device designs, EMI shielding using only a metal housing is difficult due to gaps in the enclosure (electrical discontinuity between the case and the cover), openings for ventilation, protruding cables, and other factors.

For this reason, the following materials are used for EMI shielding depending on the location of use and purpose.

| Shielding materials | Outline |

|---|---|

| Conductive elastomer | Sheet or string EMI shielding gasket made of silicone with added conductive filler |

| Soft shield | EMI shielding gasket consisting of a conductive fabric (nickel-plated nylon material) covering a urethane sponge core |

| Shield fingers | Grounding/EMI shielding product group using beryllium copper alloy as a material with particularly excellent elastic performance |

| Shield line | EMI shielding gasket made of special metal wire cloth formed into a string shape |

| Cho-Form (FIP Gasket) | Conductive silicone gasket automatically mounted on a metal or plastic housing |

| Precision expanded metal | Precision expanded metal for EMI shielding in openings where ventilation and visibility are required |

| Shield honeycomb | Honeycomb-shaped EMI shielding product group used in openings that require high air permeability |

| Conductive tape | Metal foil (copper or aluminum) tape lined with conductive pressure sensitive adhesive |

| Conductive plastic | Conductive plastic that has conductive properties made by dispersing nickel-plated graphite fibers in PC-ABS |

| Radio wave absorbers | EMI countermeasure materials that absorb electromagnetic noise. There are two types of electromagnetic wave absorbers based on different principles: suppression and resonance. |

| Permalloy tape | A magnetic shield product made of magnetic material, mainly nickel alloy, in the form of a foil |

| Shield can | Precision sheet metal parts for EMI shielding |

*Products handled by Taiyo Wire Cloth

Contact Taiyo Wire Cloth Co., Ltd. for EMI shielding

There are various types of EMI shielding, and it is essential to select the right material for the operating environment and to verify the effectiveness of EMI shielding in advance. Taiyo Wire Cloth Co., Ltd. handles a variety of EMI shielding product group such as gaskets, conductive elastomers, soft gaskets, and shield fingers.

For more information on various EMI shielding products, please visit our product pages.