Screen Mesh for Precision Printing

What is Screen Mesh?

Screen mesh is a fine mesh material mainly used in screen printing. In screen printing, it is used to transfer ink onto the substrate through the mesh. This process is crucial for achieving uniform ink transfer and high-precision printing.

What is Screen Printing?

Screen printing is a technique where ink is transferred to the substrate through a screen mesh. This technique is utilized in various industries, including textiles, electronic circuits, and advertising billboards. The selection of screen mesh is a vital factor that determines the accuracy and quality of the print.

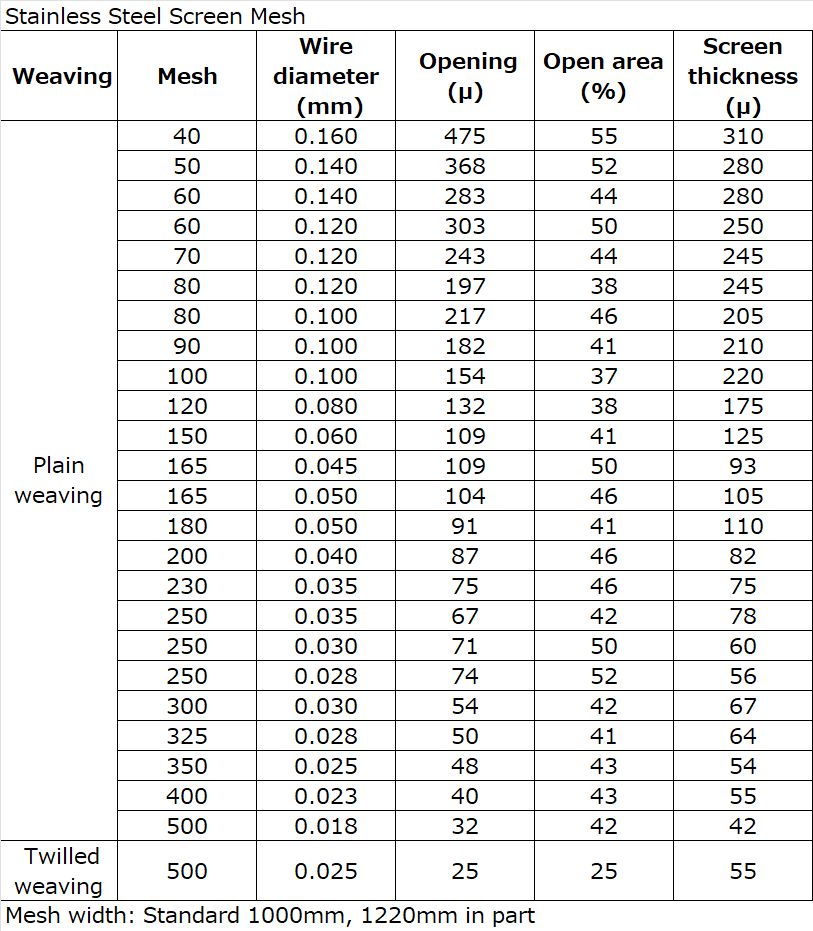

Specifications of Screen Mesh

- Wire Diameter

The wire diameter of the screen mesh refers to the diameter of the metal wires that make up the mesh. - Mesh Count

Mesh count represents the number of openings per inch in the mesh. Higher mesh counts are suitable for reproducing fine details during printing. - Open Area

Open area indicates the proportion of open spaces in the mesh per unit area.

Representative Specifications of Screen Mesh

Representative specifications of screen mesh include those made of stainless steel. Stainless steel mesh is widely used in many industries.

Role of Mesh in Screen Printing

In screen printing, selecting the appropriate mesh is extremely important. By choosing the right mesh, ink transfer efficiency is improved, print quality is maintained, and optimal printing results can be achieved. In addition to stainless steel, screen meshes made of nylon and polyester are also available.