"Positive electrode material and negative electrode material quality improvement through screen manufacturing"

Lithium-ion batteries play a crucial role in the proliferation of modern electronic devices and electric vehicles. With the growth of the lithium-ion battery market, the demand for positive electrode materials and negative electrode materials is also rapidly increasing. Market growth is expected to continue. We are committed to supporting our customers' manufacturing processes of positive and negative electrode materials by providing high-quality screens.

The functions of positive electrode material and negative electrode material

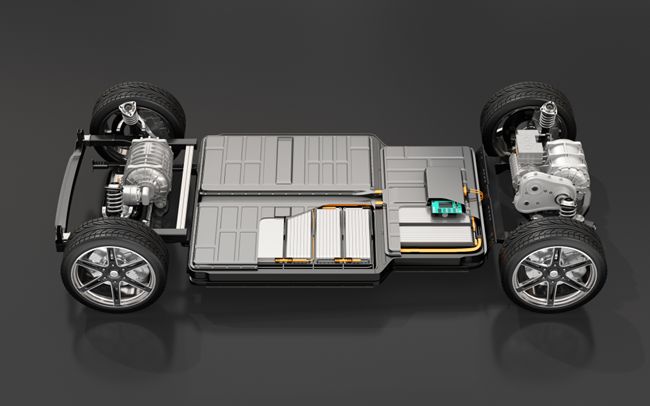

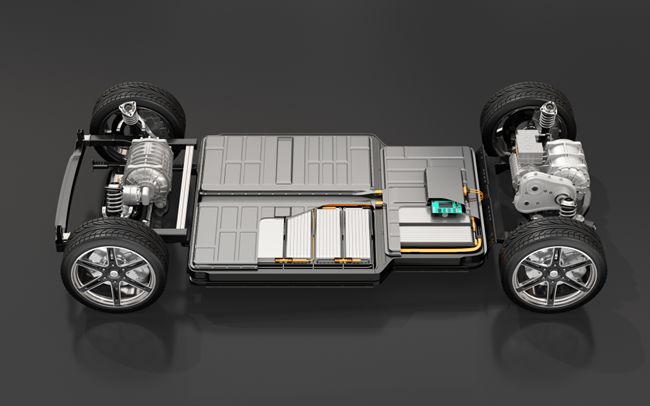

In lithium-ion batteries, lithium ions move back and forth between the positive and negative electrodes through the electrolyte during charge and discharge cycles. This charge-discharge reaction enables the battery to store electrical energy and supply power when needed. Positive electrode materials and negative electrode materials are crucial materials that influence the performance of lithium-ion batteries.

The characteristics of lithium-ion batteries

Lithium-ion batteries have numerous advantages, including high energy density, lightweight, and high voltage. They also exhibit stable charge-discharge cycles, making them suitable for a wide range of applications from electronic devices to electric vehicles. However, lithium-ion batteries also come with quality risks. One of these risks is the potential for fire hazards caused by the presence of impurities. If foreign substances, such as copper components, are mixed into the materials, they can trigger abnormal reactions inside the battery, leading to fires.

Preventing foreign object ingress

To prevent fires in lithium-ion batteries, it's crucial to prevent foreign object ingress during the manufacturing process of positive and negative electrode materials. In this regard, the manufacturing process of metal screens (high-mesh screens) that we provide to our positive and negative electrode material customers also plays a vital role. Metal screens (high-mesh screens) are used as tools for material sieving in the manufacturing process of positive and negative electrode materials. Through the sieving process, the positive and negative electrode materials are turned into uniformly sized powders. To prevent the generation of foreign objects from the metal screens during this sieving process, we implement meticulous management at every stage of screen manufacturing. This helps improve the quality of positive and negative electrode materials and reduces the risk associated with foreign object contamination.

Our solution

We are committed to manufacturing the best metal screens (high-mesh screens) for positive and negative electrode materials. In order to achieve quality improvement and enhance production efficiency, we continuously refine our screen manufacturing process and rigorously control quality.

As the lithium-ion battery market continues to grow, the demand for positive and negative electrode materials is increasing. Positive and negative electrode materials are the main components of lithium-ion batteries, and their quality directly impacts battery performance and safety. The use of metal screens (high-mesh screens) produced under strict manufacturing processes helps prevent foreign object ingress in positive and negative electrode materials, thereby improving quality. We cater to customer demands and provide services for the production of high-quality positive and negative electrode materials.