FA Equipment and EMI Countermeasures

Factory Automation Equipment

FA equipment, also known as Factory Automation, refers to a collective term for automated machinery and robots used in the industrial sector. These devices are employed to supplement human labor and achieve automation and efficiency in the production process. FA equipment is responsible for tasks that are repetitive, labor-intensive, or hazardous, and can accomplish them with high precision and speed.

There are various types of FA equipment, and three representative types are listed below:

1. Industrial robotic arms: These are mechanical arms with multiple joints used for gripping and transporting objects. They are suitable for a wide range of tasks such as assembly, welding, and material handling.

2. Collaborative robots: These are robots that can safely work alongside humans, utilizing sensors and cameras to perceive their surroundings and collaborate with humans. They are used for tasks such as assembly, inspection, and material handling.

3. AGVs (Automated Guided Vehicles): These are automated vehicles used for transporting goods within factories and warehouses. They are responsible for moving and transporting items.

Currently, FA equipment is widely applied in various industries, including automotive manufacturing, electronics assembly, food processing, and warehouse logistics. Factors such as increasing demand for automation, labor shortages, and the need to enhance competitiveness are expected to drive the growth of the FA market. Additionally, advancements in technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) are promoting the advancement and expanded application scope of FA equipment.

Moreover, there is significant interest in the next-generation "smart factory," where various equipment within the factory is connected to the internet and becomes part of the Internet of Things (IoT). Wireless communication is also utilized in industrial robots, for example, with AGVs autonomously navigating based on 5G technology. FA equipment with communication units needs to consider EMI countermeasures in their product design.

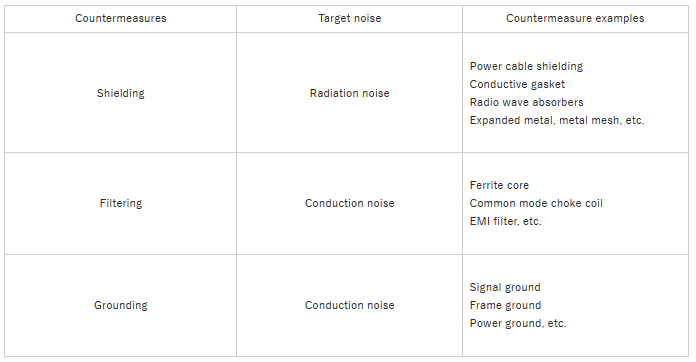

Types of EMI Countermeasures

There are various methods for EMI countermeasures, and the following are representative methods.

Power cables and communication cables, among others, not only serve as pathways for noise propagation but also generate radiation noise themselves. Therefore, measures must be taken with physical protection of the wires and shielding against electromagnetic waves as the starting point.

Types of EMI Shielding

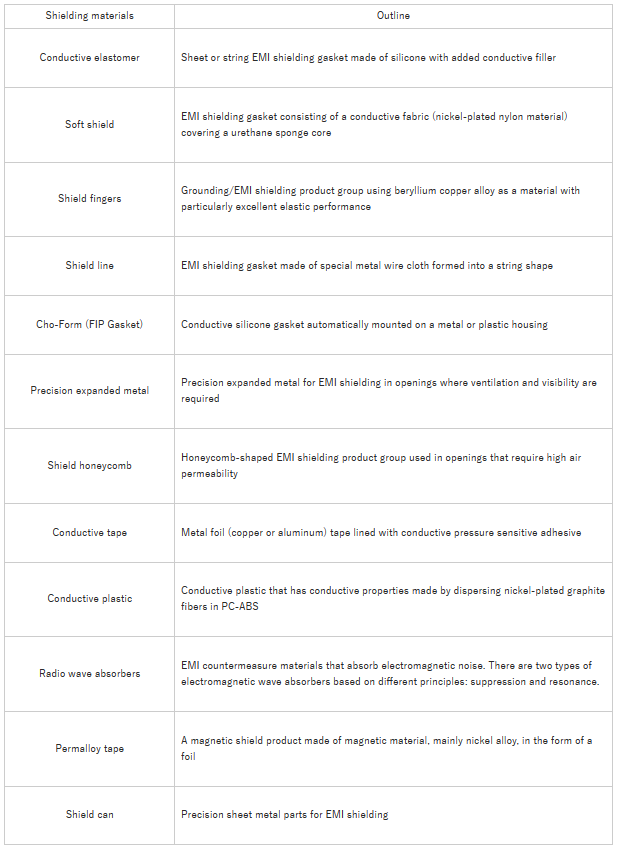

To enhance the noise attenuation effect of EMI shielding, the ideal approach is to surround the noise source with materials of high electrical conductivity and magnetic permeability without leaving any gaps. While metal plates are expected to provide high EMI shielding effectiveness as frame materials, in reality, achieving EMI shielding solely with metal frames is challenging due to the presence of frame gaps (electrical discontinuities between the housing and cover), ventilation openings, cable protrusions, and other factors in actual equipment design.

Therefore, depending on the usage scenario and purpose, the following materials are commonly used for EMI shielding:

For inquiries regarding EMI shielding, please contact Taiyo Wire Cloth Co., Ltd.

EMI shielding comes in various types, and it's crucial to select materials based on the usage environment and verify the EMI shielding effectiveness in advance. Taiyo Kinzoku Co., Ltd. offers a variety of EMI shielding products such as gaskets, conductive rubber, sponge gaskets, and shielding spring plates.

For more information about these EMI shielding products, please refer to the product pages on their website.