Semiconductor Manufacturing Equipment and Electromagnetic Interference (EMI) Mitigation

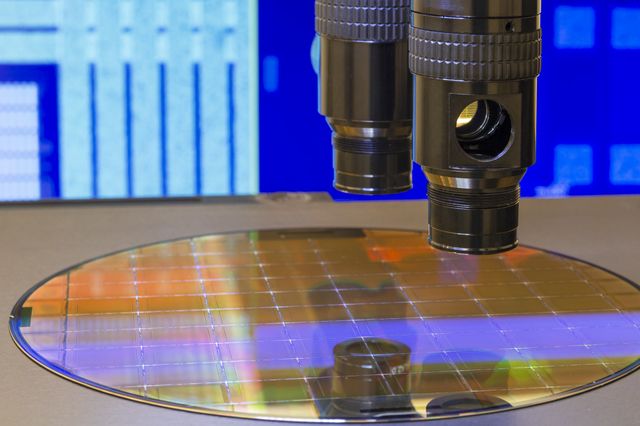

Semiconductor Manufacturing Equipment

Semiconductor manufacturing equipment demonstrates very high growth potential in the rapidly expanding modern technology industry. Semiconductors are indispensable key technologies in various industries such as smartphones, computers, automobiles, artificial intelligence, and cloud computing. The growth and advancements in these industries are driving the rapid increase in demand for semiconductors, which in turn is boosting the demand for semiconductor manufacturing equipment.

Semiconductor manufacturing equipment is used to carry out the semiconductor manufacturing process. Although there is a wide variety of equipment, the main types used in key processes include etching equipment, chemical vapor deposition (CVD) equipment, photolithography equipment, and testers.

Etching Equipment: Used to remove layers and patterns from semiconductor wafers. It selectively etches specific areas on the wafer surface using chemical reactions or plasma.

Chemical Vapor Deposition (CVD) Equipment: Utilizes gas-phase precursors to grow thin films on semiconductor wafers. Precursor gases are supplied to the wafer, where they react chemically to form the film.

Photolithography Equipment: Used to form fine circuit patterns on semiconductor wafers. It transfers patterns from a mask onto the wafer using light.

Testers: Used to test the functionality and quality of manufactured semiconductor devices. They perform tasks such as sending and receiving signals, measuring electrical characteristics, and operational testing.

With the advancement of the latest technologies, there is an increasing demand for semiconductor miniaturization and high performance. Therefore, more advanced manufacturing equipment needs to be developed for various manufacturing processes. To ensure the proper operation of these semiconductor manufacturing equipment, electromagnetic interference (EMI) design must be implemented to prevent interference.

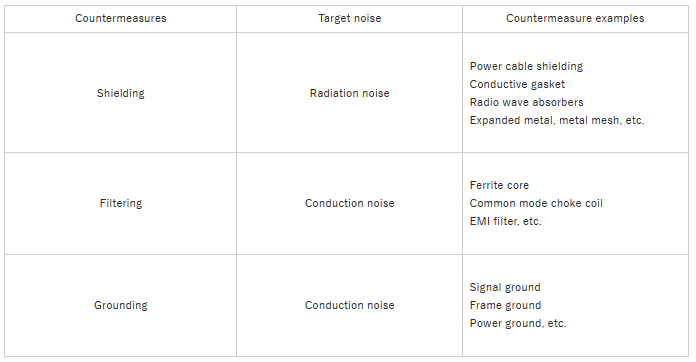

Types of EMI Countermeasures

There are various methods for EMI countermeasures, and the following are representative methods.

Power cables and communication cables, among others, not only serve as paths for noise propagation but also generate radiation noise. Therefore, measures must be taken with physical protection of the wires and shielding against electromagnetic waves as a starting point for countermeasures.

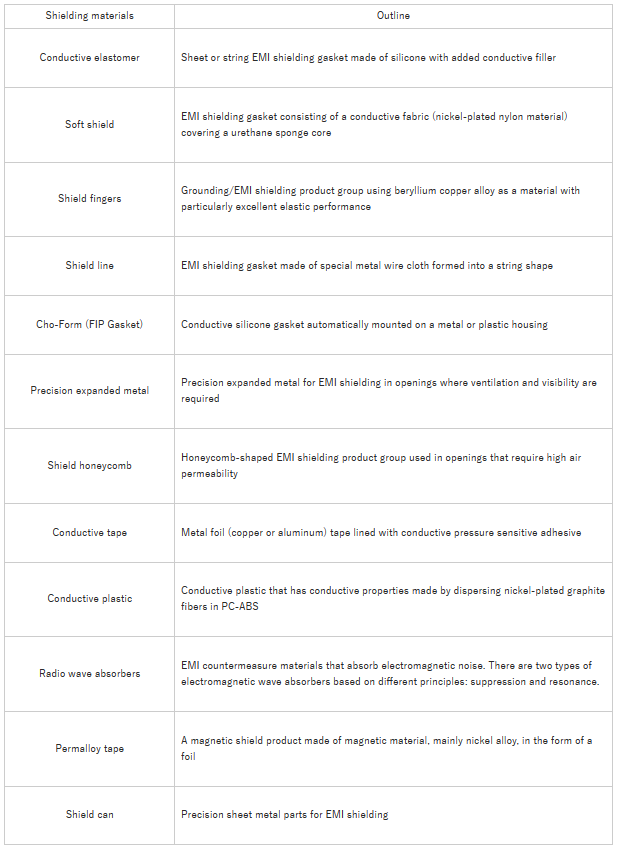

Types of EMI Shielding

In order to enhance the noise attenuation effect of EMI shielding, the ideal approach is to surround the noise source with materials of high conductivity and magnetic permeability without any gaps. While metal plates as frame materials are expected to achieve high EMI shielding effectiveness, in practical equipment design, achieving EMI shielding solely with metal frames is challenging due to the presence of frame gaps (electrical discontinuity between the enclosure and cover), ventilation openings, cable protrusions, etc.

Therefore, depending on the usage scenario and purpose, the following materials are used for EMI shielding.

For inquiries about EMI shielding, please contact Taiyo Wire Cloth Co., Ltd.

EMI shielding comes in various types, and it's crucial to select materials based on the usage environment and validate the EMI shielding effectiveness beforehand. Taiyo Kinzoku Co., Ltd. offers a variety of EMI shielding products such as gaskets, conductive rubber, sponge gaskets, and shielding spring contacts.

For details about the various EMI shielding products, please refer to the product pages.