- What Is XR? | Devices in Use/EMI Shielding & Thermal Management

- What is XR?

- Applications utilizing XR

- Devices used for XR

- Various problems with XR devices

- For more information about EMI and thermal problems of XR devices, contact Taiyo Wire Cloth.

- EMI countermeasure materials and thermal management materials for XR devices and peripherals

- For more information about EMI countermeasure materials and thermal management materials, contact Taiyo Wire Cloth.

What Is XR? | Devices in Use/EMI Shielding & Thermal Management

As the process of DX progresses, XR devices, including AR and VR, are seeing increasing use in innovative user experiences. In the manufacturing industry, these devices are beginning to be used in applications such as MR design verification using 3D models.

Various XR devices are beginning to be widely used for virtual experiences. These include existing smartphones, head-mounted displays (HMDs), and AR/MR glasses. As these XR devices and peripherals become more sophisticated, various troubleshooting measures are required.

This section describes the basics of XR, the devices and peripherals used, and various problems and their countermeasures.

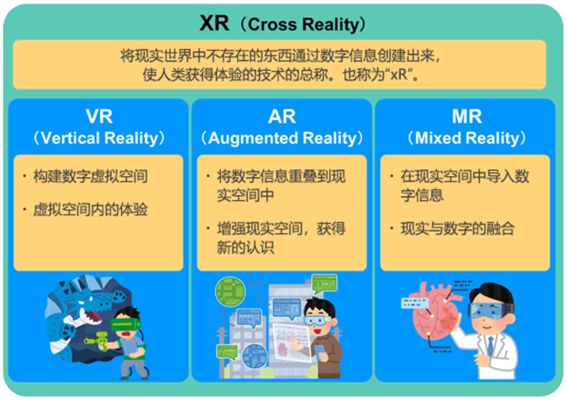

What is XR?

XR: Cross Reality is a generic term for technologies that create digital information about things that do not exist in front of us and allow us to interact with them by merging virtual and real spaces. The X in XR can be replaced by various words to describe virtual experience technologies such as VR, AR, and MR.

VR (virtual reality)

In Virtual Reality (VR), an omnidirectional virtual space is digitally created, and people can interact virtually in that space by using a controller or conversing with an avatar.

AR (augmented reality)

In Augmented Reality (AR), the real world is augmented by overlaying various digital information, such as computer graphics, on visible real space. Shopping and guidance apps that utilize AR have seen practical use.

MR (mixed reality)

In Mixed Reality (MR), the augmented reality of AR is combined with 3D models of VR, etc. so that people can have various virtual experiences where the real world and a virtual space overlap.

Applications utilizing XR

Various applications utilizing XR are already in practical use and further development is underway. Here we will introduce some examples of XR implementation.

Examples of XR applications

Typical examples of XR applications include VR software for console games such as PlayStation VR and AR game apps such as Pokémon GO.

The use of ICT in school education is also increasing, and XR-based educational programs are being considered. In the tourism industry, AR-based tourism apps are being created, and mobility linkages are being developed.

Introduction of XR technology in manufacturing

The use of XR in manufacturing is also increasing. In order to pass on the skills of experienced workers to younger workers in a safer and more efficient manner, training is being conducted using XR training simulations. In addition, when starting up a production line at a factory, the use of 3D models and MR makes it possible to project virtual production equipment in spaces where equipment is to be installed, as if it were actually in front of workers at the factory. This virtual equipment can be used to check the line layout and verify workability and safety of the equipment in advance. MR devices are also being used in product design and development to simulate prototypes.

Devices used for XR

Hardware and software are essential for XR virtual experiences, and XR requires the following devices.

Current XR devices

One particularly well-known type of devices used for XR is Head-Mounted Displays (HMD), a type of wearable device.

An HMD is a display worn on the head, and is typically non-transmissive, such as the Oculus Quest, which completely covers the field of vision to increase immersion in the VR space. There are also transmissive MR head-mounted displays, such as HoloLens 2, with eye and hand tracking capabilities to allow users to have virtual experiences with greater affinity to the real space.

Future XR devices

XR devices are sometimes mentioned as candidates for post-smartphones, and the XR market is expected to grow in the future. With 5G (6G in the future) high-speed communications, higher performance CPUs, and micro-LED technology applied to XR displays, future XR devices will be much more advanced, smaller, and lighter with form factors such as smart glasses, and will likely be indispensable in our daily lives and businesses, just like today's smartphones.

Various problems with XR devices

Devices such as HMDs and MR/AR glasses used for XR as well as peripheral devices are becoming more sophisticated.

HMDs, for example, are increasingly becoming wireless stand-alone devices, and electronic components are becoming more integrated, smaller, and lighter in order to increase the amount of data that can be transmitted and improve processing speed. This trend leads to two major problems: EMI and heat issues.

EMI problems

EMI (Electromagnetic Interference) refers to electromagnetic noise emitted by various electronic components used in devices during operation which can have various adverse effects on other electronic equipment.

Since XR devices are electronic devices, they generate electromagnetic waves because they use electricity in their operation. This means that the following problems may occur.

Malfunctions in devices and other electronic equipment

XR devices and other surrounding electronic devices generate electromagnetic radiation. Although such devices use various EMI countermeasures and are designed with EMC in mind, electromagnetic noise can cause malfunctions, especially if there are older devices with inadequate EMC.

Communication failures

XR devices may use Wi-Fi for data communication or Bluetooth for device-to-device connections. Some also utilize high-speed, high-capacity communications over 5G. Devices in close proximity to each other in a radio band may cause interference that slows communication speeds and other problems.

Heat problems

Immersion and reality are important in XR, and devices are designed with an emphasis on UI/UX, and are being downsized to reduce the physical burden on the user. As a result, the density of electronic circuits and other components has increased, making heat dissipation more difficult.

In addition, depending on the intended use, it may be difficult to mount a fan to eject heat from the device due to vibration and noise issues. Furthermore, HMDs often use resin casings, which are more difficult to dissipate heat from than metal casings, and may cause the following problems.

Device quality deterioration

Generally speaking, electronic components have a shorter life span if they continue to operate at high temperatures, which can lead to premature failure of the device itself. In addition, electronic circuits are composed of materials with different coefficients of thermal expansion. Repetitive stresses of changing between room temperature and high temperature conditions can cause thermal fatigue in lead wires, etc., resulting in mechanical deterioration and damage.

Safety problems during use

It has been confirmed that if electronic devices generate heat and come into contact with the skin for a prolonged time, they can cause low-temperature burns. In particular, heat generation in wearable devices such as XR devices involves safety issues for the human body.

To address such thermal problems, thermal simulations are performed from the design stage, and risks can be reduced through the use of thermal management materials.

For more information about EMI and thermal problems of XR devices, contact Taiyo Wire Cloth.

Taiyo Wire Cloth Co., Ltd. offers a wide variety of products through its thermal management and EMI shielding technologies. If you have concerns about thermal or EMI problems in XR devices, please feel free to contact us.

EMI countermeasure materials and thermal management materials for XR devices and peripherals

To solve EMI and thermal problems in XR devices, we can propose the following methods and countermeasure components.

EMI countermeasure materials for XR devices

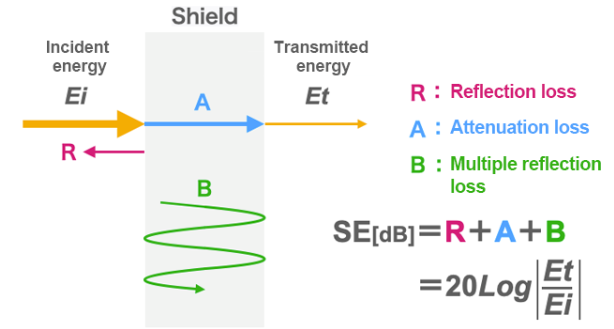

EMI shielding is particularly effective in preventing EMI due to radiated noise. EMI shielding is a component that reduces the amount of electromagnetic energy leakage by utilizing the shielding effects of electromagnetic wave reflection, attenuation, and multiple reflections in shielding material.

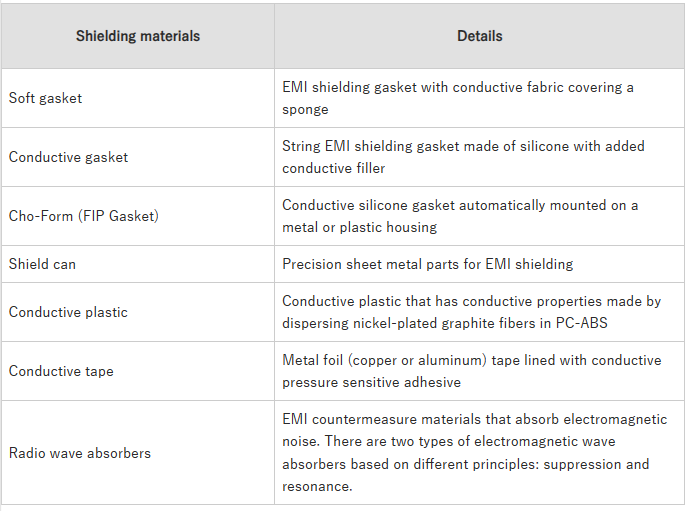

Types of EMI shielding

The ideal way to reduce the transmission of electromagnetic waves with EMI shielding is to enclose the noise source in a highly conductive material, such as a metal casing. However, due to device design restrictions and other factors, the following alternative EMI shielding components can be effective countermeasures.

The following materials can be selected for EMI shielding depending on the structure and intended use of the device.

Thermal management materials of XR devices

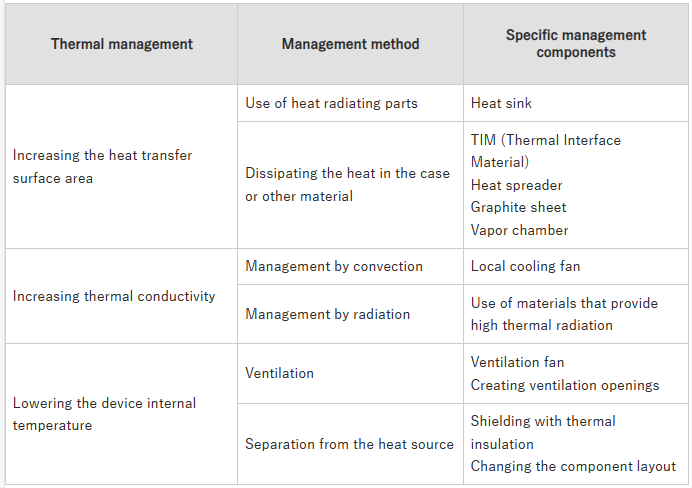

To quickly release heat from XR devices to the outside and avoid problems, the following thermal management, such as heat dissipation, are used.

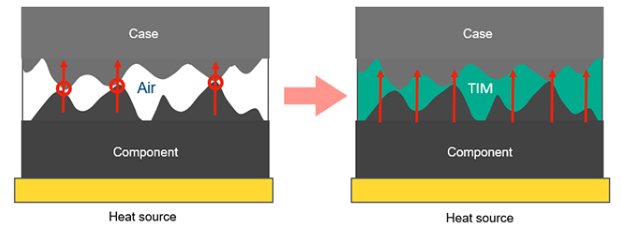

It is difficult to install fans in XR devices and peripherals, so it is important to efficiently diffuse the heat generated internally to the casing and heat sinks. To achieve this, the contact thermal resistance between heat sources, such as CPUs, and the heat dissipation areas, such as casings, must be lowered.

To lower the contact thermal resistance, using TIM to fill the minute gaps between the components and between the casing and the components is an effective technique.

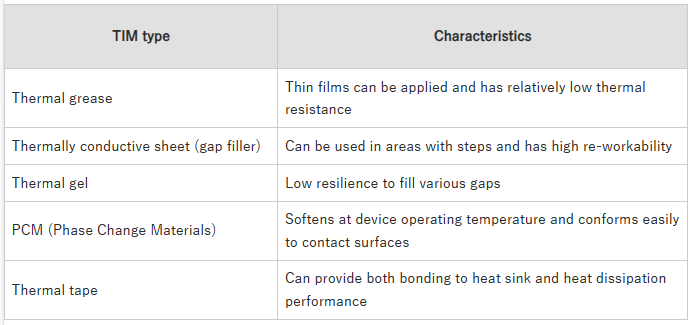

TIM types and characteristics

There are various types and characteristics of TIMs, and if the appropriate one is not selected depending on the application and location of use, it may not provide the expected thermal management effects.

For more information about EMI countermeasure materials and thermal management materials, contact Taiyo Wire Cloth.

For XR device thermal management materials and EMI shielding, prior verification of effectiveness is essential, in addition to material selection according to the operating environment. Taiyo Wire Cloth offers a lineup of thermal management products, including gap fillers, thermal gels, and thermally conductive sheets, as well as EMI shielding products.

For more information on each product, please visit our product pages.