Etching Metal

Etching Metal

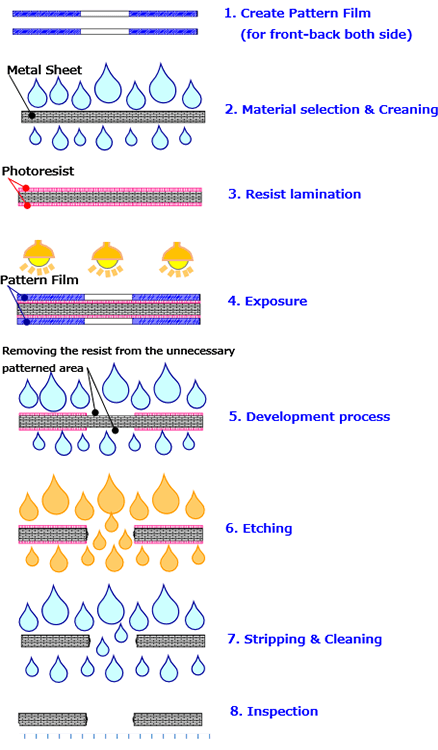

Etching is done by removing unnecessary parts through chemical corrosion after an anti-corrosion mask treatment has been applied. This manufacturing process allows TWC to meet precision requirements that cannot be achieved with press punching, allowing us to specialize in products with ultra-thin, ultra-small and complex hole shapes. TWC can supply products for applications such as mic and speaker mesh for smartphones and tablets, mesh filtration filters, and encoder scales.

◆ Etching metal uses:

Mic/speaker mesh for smartphones/tablets

Mesh filters

Precision springs

Linear encoder scales

Rotary encoder discs

◆Advantages of etching metal:

• Using a precise photomask to determine the shape pattern makes it possible to perform micron-order complex microfabrications.

• Etching metal makes it possible to achieve a narrow pitch shape that is not possible with press dies.

TWC ensures high-precision machining with no burrs or distortion and no hardening of workpieces.

Because no jigs are used, initial costs can be kept to a minimum.

Regardless of the shape or size of the area being processed, we are able to process products with a short delivery time.

Mass production is also possible by processing multiple pieces at the same time.

Combining etching metal with press processing also makes three-dimensional processing possible.

◆Etching metal materials:

Stainless steel, copper/copper alloys, aluminum, phosphor bronze, brass, beryllium copper, nickel, titanium, etc.

◆Etching processes:

Product Group