2021.09.13

Low-Temperature Silver nanoparticle bonding material paste with High Heat Resistance and Thermal Conductivity FlowMetal™

Modern electronic device designs generate extremely high amounts of heat, which has led to a need for better heat countermeasures. As requirements for heat resistance and thermal conductivity have increased, it has become more and more difficult to use conventional low-temperature solder when joining materials. Reducing environmental impacts must also be considered, so products must be lead-free and RoHS 2-compliant. Cost is another important factor.

Nanoparticle-based FlowMetal™ bonding material--a low-temperature silver nanopaste sintering material from Bando Chemical Industries, Ltd.--offers both excellent heat resistance and high thermal conductivity. This material uses silver nanoparticle technology to allow for pressure-free bonding at low temperatures. It also offers better cost reductions than AuSn solder, which has a high melting point. This material can provide high bonding reliability in devices that generate high amounts of heat, including powered semiconductors for inverters, high-frequency 5G devices, and high-power lasers for next-generation optical communications.

Low-temperature sintering at 200°C or less with high heat resistance

FlowMetal™ low-temperature sintering bonding material uses silver nanoparticles to provide not only low bonding temperatures but also high heat resistance. With conventional solders, bonding is performed by melting the solder material. When using solders with a low melting point on components in devices that generate a lot of heat, the solder may melt if the temperature reaches the melting point of the solder. On the other hand, solders with a high melting point, such as AuSn solder, offer higher heat-resistance temperatures but require higher temperatures for bonding, which limits where these materials can be used. Such solders also contain gold, which increases costs.

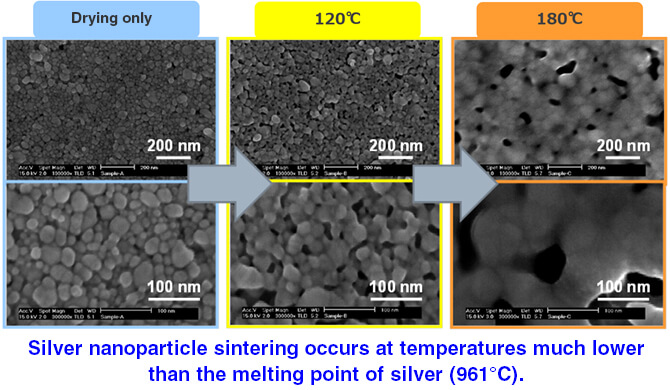

With FlowMetal™, sintering bonding is possible at temperatures as low as 150°C (Note 1) thanks to the low-temperature sintering properties of the nanoparticles. After sintering, the material has the inherent melting point of silver (approx. 961°C), highlighting its high heat resistance. Bonding with silver sintering allows for high thermal conductivity. Compared with solder that contains gold, FlowMetalTM is both less expensive and lead-free, so it can reduce both cost and environmental impact. It also complies with all usage restrictions set forth under the RoHS 2 Directive.

As electronic devices have become faster and more powerful in recent years, the amount of heat generated has also increased dramatically. In addition to their high-performance capabilities, small, high-power ICs such as FPGAs and GPUs, next-generation compound semiconductors such as GaN and SiC, and high-frequency 5G devices are prone to high temperatures, making thermal control difficult.

To ensure stable operation even at high operating temperatures, the bonding materials used in these devices require high heat resistance and high thermal conductivity. FlowMetal™ can provide the high performance required for electronic devices that operate at high temperatures while also contributing to longer service lives and improved reliability.

Pressure-free, low-temperature bonding material with high heat resistance and advanced thermal conductivity

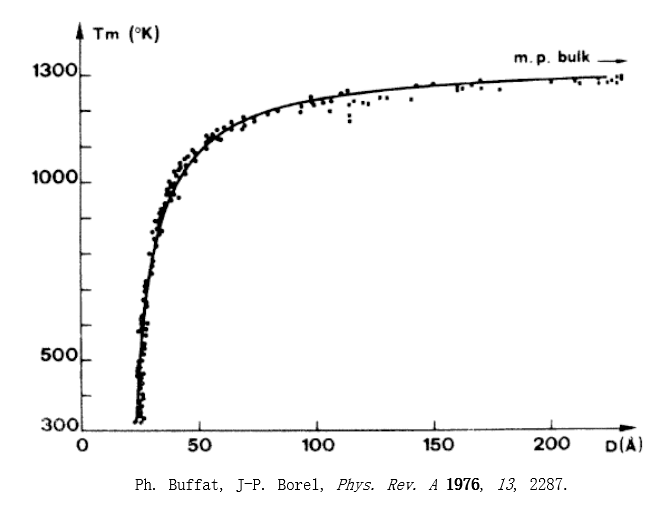

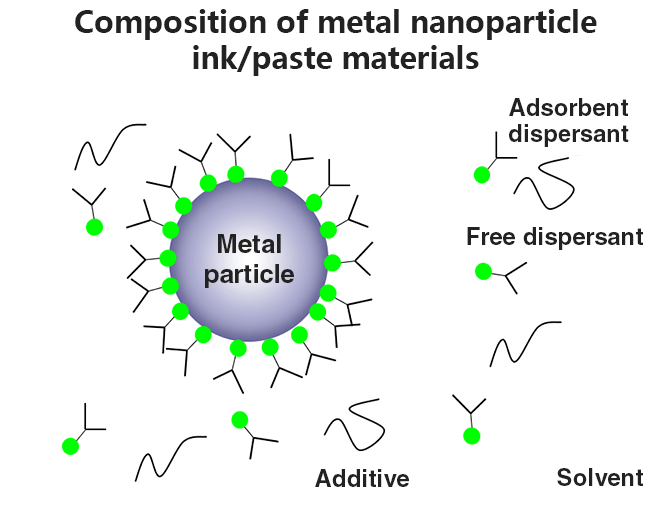

FlowMetal™ is a paste-type bonding material made with silver nanoparticles that include surface-absorbed dispersant. The melting point of metal particles is low at smaller sizes and high after sintering. This characteristic is even more pronounced with nano-sized particles, and FlowMetalTM utilizes these properties to offer low-temperature sintering and high post-sintering heat resistance.

Ph. Buffat, J-P. Borel, Phys. Rev. A 1976, 13, 2287.

Fig. 1 -- Relationship to size of silver nanoparticles

General-purpose conductive resin paste that contains silver provides thermal conductivity performance depending on the amount of silver it contains, but bonding is performed as the resin hardens and deterioration due to heat is a concern as heat resistance cannot be assured. Solder, on the other hand, is heated to the melting point for bonding, so heat resistance is determined by the melting point of the solder material. During this process, the material is heated to temperatures higher than its melting point, so there are restrictions on what devices can be bonded. When using low-temperature sintering with silver nanoparticles for bonding, there are not many restrictions on the applicable materials, and high heat resistance, thermal conductivity, and shear strength are ensured.

One drawback of nanoparticles is that they are activated as the surface area increases, resulting in poor sintering and low dispersibility. FlowMetal™, however, is made with optimal dispersants for superior dispersion stability and can deliver high silver particle concentrations (85 to 97 wt%) in a stable dispersion in solvents. With pressure-free, low-temperature bonding, there is also no need for large pressure adjustment equipment. Following dispensing or metal mask printing, devices can be mounted and fired in an existing hot air circulation or reflow furnace for bonding. In other words, no additional investments are necessary, including for pressure-free bonding to copper (Note 2).

Supporting bonding in next-generation electronics

In addition to excellent heat resistance and thermal conductivity, FlowMetal™ can be sintered at temperatures as low as 150°C (Note 1) with no pressure required, making it ideal for bonding applications in next-generation electronic devices.

When it comes to FPGAs, GPUs, and other small, high-power ICs--which are being used more frequently in image-processing, AI-based analysis, and automated driving--countermeasures against heat are essential. Next-generation compound semiconductors such as GaN and SiC are also increasingly being used in power semiconductors for controlling large amounts of power, including in electric vehicles and renewable energy generation. These large amounts of power result in high operating temperatures and the need for similar heat countermeasures. In addition, as the output of optical devices such as high-power lasers for next-generation optical communications, high-brightness and high-power LEDs, and UV LEDs capable of replacing mercury lamps increase, so does the amount of heat these devices generate. To counter that heat, low-temperature bonding material with a high heat resistance is needed. High-frequency devices for 5G and other high-speed communications--which use higher frequencies--are becoming more widespread and smaller than ever, so heat countermeasures are urgently needed.

FlowMetal™ can help meet the needs for electronic devices that require higher quality and stable operation despite the large amounts of heat generated.

Note 1: With the SR9200

Note 2: With the SR9870

FlowMetal™ is a trademark of Bando Chemical Industries, Ltd.